Laboratory Guide: Determination of Pesticide Residues According to AOAC 970.52, 985.22, and 970.53 (1990)

- Laboratory Guide: Determination of Pesticide Residues According to AOAC 970.52, 985.22, and 970.53 (1990)

Standard Operating Procedure (SOP)

1.0 Scope

This SOP applies to the detection and quantification of pesticide residues in fruits, vegetables, and plant-based matrices, following AOAC 970.52, 985.22, and 970.53.

2.0 Principle

Pesticides are extracted using solvents, purified by Florisil/silica cleanup, concentrated, and quantified via Gas Chromatography (GC) with selective detectors:

ECD (Electron Capture Detector): Organochlorines

NPD (Nitrogen Phosphorus Detector): Organophosphates and Organonitrogen

FPD (Flame Photometric Detector): Organophosphates

3.0 Responsibilities

Analyst: Conducts the procedure and maintains records.

Supervisor: Reviews QC, validates results.

QA Officer: Ensures compliance with accreditation standards.

4.0 Safety and Precautions

Checklist before starting work:

☐ Lab coat, nitrile gloves, goggles

☐ Certified fume hood operational

☐ MSDS for solvents available

☐ Waste containers labeled (halogenated vs non-halogenated)⚠️ Hazards:

Solvents: Flammable and toxic → avoid ignition sources.

Standards: Extremely toxic → handle only with calibrated pipettes.

Florisil dust: Respiratory hazard → wear mask if handling dry powder.

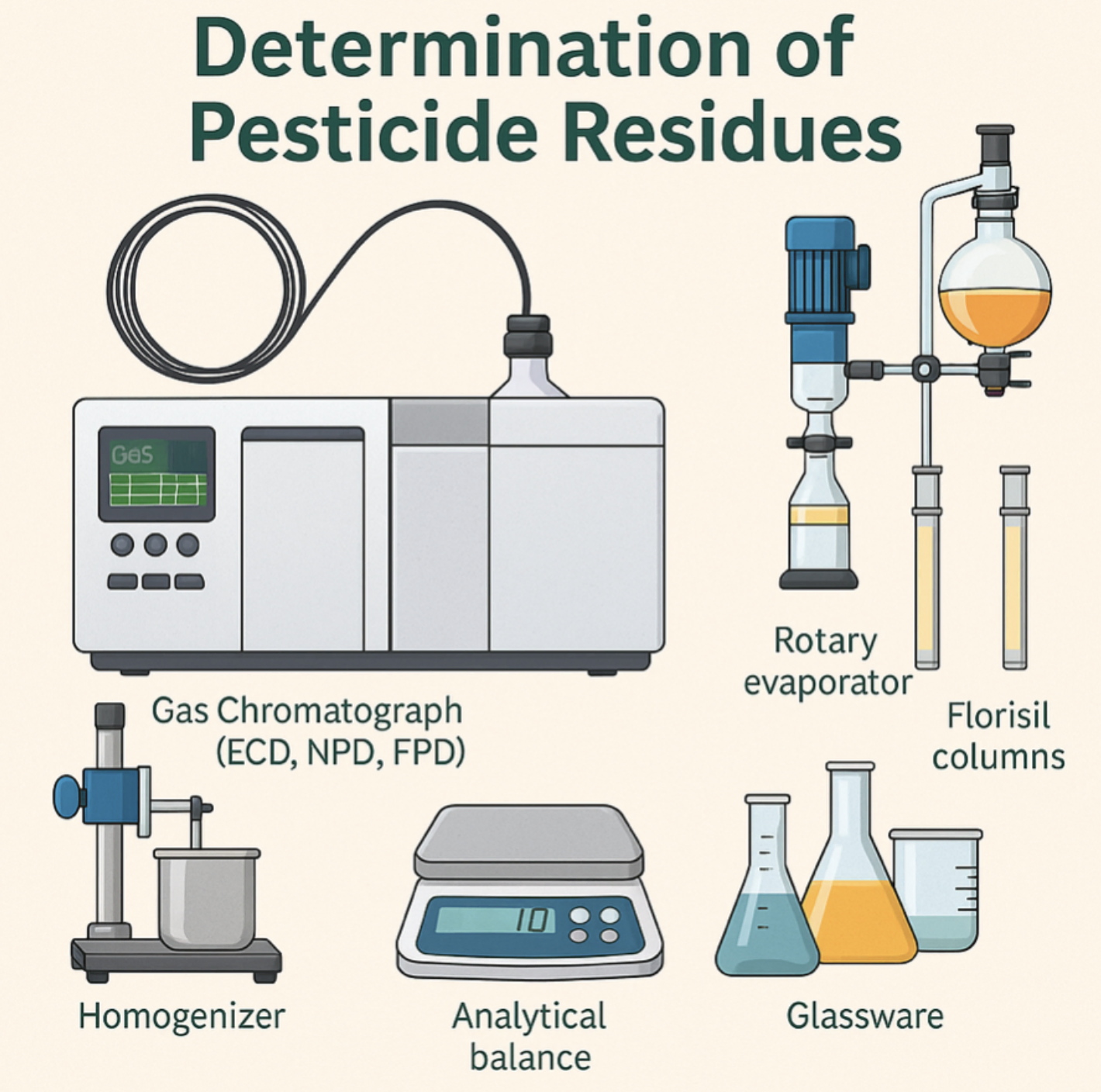

5.0 Equipment and Apparatus

Gas Chromatograph with ECD, NPD, FPD

Capillary columns DB-5 or DB-1701 (30 m x 0.25 mm x 0.25 μm)

Homogenizer (stainless steel jar)

Analytical balance (±0.1 mg)

Rotary evaporator with water bath ≤40 °C

Kuderna-Danish (K-D) concentrator tubes with Snyder column

Florisil glass columns with Teflon stopcock

Volumetric flasks, pipettes, centrifuge (optional)

6.0 Reagents and Standards

Solvents (residue grade): Acetonitrile, Petroleum Ether, Hexane, Acetone, Dichloromethane, Ethyl Acetate

Sodium Sulfate (anhydrous, pre-baked 600 °C, stored sealed)

Florisil (60–100 mesh, activated 675 °C, deactivated 1–2% water)

Certified pesticide standards (DDT, Malathion, Lindane, Carbaryl, etc.)

Calibration standards (multi-level: 0.01–0.5 µg/mL)

7.0 Procedure

7.1 Sample Preparation

Collect representative sample (50–100 g).

Homogenize using blender/homogenizer until uniform.

Record sample weight in logbook.

7.2 Extraction

AOAC 970.52 & 970.53 (Organochlorines, Organophosphates):

Add 200 mL acetonitrile to 50 g sample.

Blend 2–3 min.

Filter homogenate into suction flask.

Transfer 100 mL extract to separatory funnel.

Add 100 mL petroleum ether → shake.

Add 500 mL sodium sulfate solution (10%) → shake.

Discard aqueous layer, retain petroleum ether layer.

Wash extract twice with 100 mL sodium sulfate solution.

Pass through sodium sulfate drying bed.

AOAC 985.22 (Organonitrogen pesticides):

Extract with dichloromethane.

Partition into acetonitrile-saturated hexane (removes fats).

Back-extract into dichloromethane.

7.3 Cleanup (Florisil Column Chromatography)

Pack glass column:

Glass wool → 2 cm Na₂SO₄ → 10–15 g Florisil → 2 cm Na₂SO₄

Condition with 50 mL petroleum ether.

Load concentrated extract.

Elute sequentially:

Fraction 1: 200 mL (6% ether/petroleum ether) → HCB, Lindane

Fraction 2: 200 mL (15%) → Aldrin, Dieldrin

Fraction 3: 200 mL (50%) → Malathion, Parathion

7.4 Concentration

K-D concentrator + Snyder column in 40 °C bath.

Reduce volume to 5–10 mL.

Final concentration under N₂ → 1–2 mL (hexane).

7.5 GC Analysis

Carrier gas: Helium/Hydrogen.

Injection: 0.5–1 µL, splitless.

Injector temp: 250 °C.

Oven: 80 °C (1 min) → ramp 10–15 °C/min → 280 °C (hold 10 min).

Detector temps: ECD 320 °C; NPD 280 °C; FPD 250 °C.

Run calibration standards and samples.

Confirm retention times vs standards.

8.0 Quality Control (QC)

QC Parameter Frequency Acceptance Criteria Method Blank 1/batch No pesticide detected LCS (spiked sample) 1/batch Recovery 70–120% Duplicate sample 1/batch RSD ≤20% Calibration check Every 10–12 injections ±20% of initial response 9.0 Calculations

Residue (mg/kg or ppm) = (C × V) / (W × R)

Where:

C = Analyte concentration in extract (µg/mL)

V = Final extract volume (mL)

W = Sample weight equivalent (g)

R = Recovery correction (if applied, else R=1)

10.0 Records

Sample logbook entries

Extraction sheets

GC run sheets with chromatograms

QC summary report

11.0 Method Limitations

Historical AOAC methods → limited for modern pesticides.

Not confirmatory (requires GC-MS/MS).

Possible matrix effects.

- For more information:

? : Contact Us