10 TPH palm oil production line

- 10 TPH palm oil production line

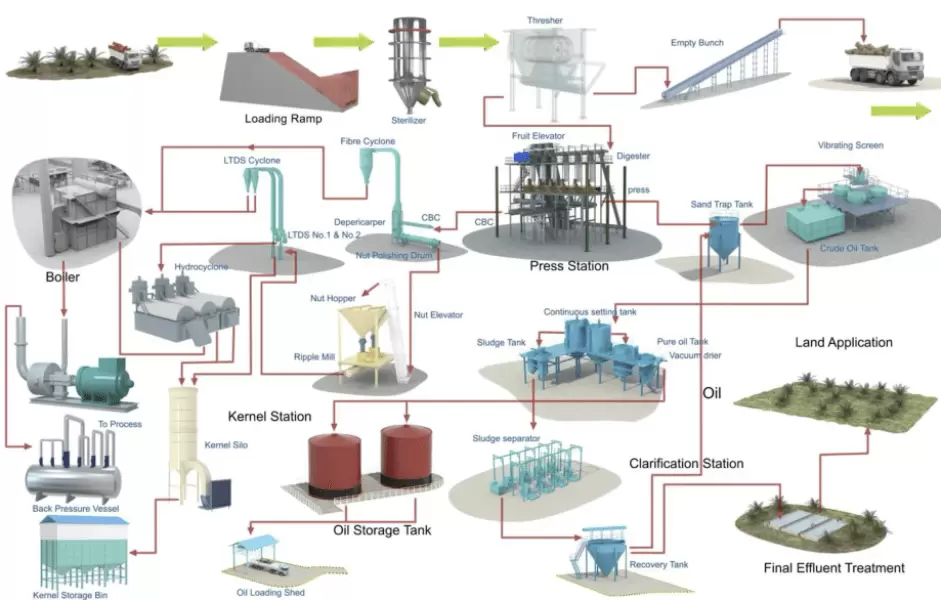

? Process Flow – Detailed Engineering View

?️ FFB Reception, Weighing, Traceability

Truck intake & weighbridge: 60–80 t capacity, legal-for-trade; auto ID + ticketing linked to MES/ERP for lot genealogy.

Unloading & buffering: side/rear tippers, grille pits, chain/belt feeders with VFDs (Variable Frequency Drives) for steady 10 TPH feed.

Sampling & QC: FFB ripeness index, debris %, moisture, temperature; camera-counting optional.

Target KPIs: ±0.05% weighbridge accuracy; <0.5% extraneous matter at reception.

? Sterilization (Saturated Steam)

Vessels: horizontal cage batch (2–4 cages × 2.5–3.5 t/cage) or continuous/vertical.

Steam conditions: 3.0–4.0 bar(g), 143–152 °C; cycle 60–90 min (incl. venting & blow-down).

Objectives: lipase inactivation (limit FFA = Free Fatty Acids rise), fruit softening, micro‐load reduction.

Condensate recovery: 60–80% to hotwell/DA (deaerator); flash steam to feedwater preheat.

Controls: recipe-based sequence, pressure ramps, cold-spot thermocouples, interlocks on doors & pressure relief.

? Threshing

Equipment: heavy-duty rotary drum thresher(s), adjustable 18–22 rpm; replaceable lifters.

Outputs: fruitlets → digestion; EFB (Empty Fruit Bunches) → mulching/compost or boiler co-fuel (after shredding/drying).

KPI: fruit stripping loss < 1.0% of total fruit.

? Digestion

Steam-jacketed digesters: 2–3 vessels × 6–10 m³ each; residence 20–30 min; 90–95 °C slurry temperature.

Agitation: multi-stage paddles (20–35 kW per vessel).

Goal: rupture mesocarp cell walls; create pumpable mash with optimal viscosity for pressing.

? Pressing

Twin-screw presses (preferred): 2 × 6–8 TPH (N+1 redundancy possible) or single-screw at higher specific power.

Operating window: 90–105 °C feed; choke cone adjustable; dilution water 8–12% on slurry as needed.

Outputs: press liquor (oil + water + fines) → clarification; press cake → fiber–nut recovery.

KPIs: residual oil in press cake ≤ 5–7% (wb); oil yield 20–23% on FFB.

? Screening & Sand Trap

Vibrating screens: 1.5–3.0 mm apertures; hot liquor 80–90 °C.

Sand trap tanks: residence 15–25 min; velocity < 0.3 m/s to settle grit.

KPI: < 100 ppm grit to clarifier/decanter; improved purifier life.

? Clarification & Purification

Two options (often combined):

Gravity clarification: continuous settling tanks (1–2 h HRT) + skimming → sludge centrifuge.

Centrifugal train: feed heaters → decanter centrifuge (20–35 m³/h) → disc-stack purifier (10–25 m³/h).

Targets: moisture ≤ 0.25%, impurities ≤ 0.25% in CPO (Crude Palm Oil).

Heat integration: plate heat exchangers to control viscosity; sludge oil recovery via decanter.

?️ Vacuum Drying & Storage

Vacuum dryer: 70–95 °C at 50–150 mbar to reduce final oil moisture → stability.

Storage tanks: insulated, steam coils, high-level/overfill & foam sensors, nitrogen blanketing optional; API-style breather valves.

Instrumentation: temperature/level transmitters, water-in-oil analyzers (optional), sampling ports.

? Fiber–Nut Separation

Depericarper + air-knife: fiber lifted off; nuts fall by gravity.

Fibers: return to boiler as fuel (after fluffing); helps maintain furnace bed.

? Nut Cracking & Kernel Separation

Ripple mills crack nuts; hydrocyclones/air tables split shell vs. kernel.

Kernel dryers: 60–70 °C to safe moisture for storage; PKO (Palm Kernel Oil) line feed.

PK yield: 5–7% on FFB (fruit quality dependent).

? Boiler & Power House (Biomass CHP)

Fuel: press fiber (~12–14% FFB), shell (~6–7% FFB), optionally shredded EFB (20–23% FFB after partial drying) & biogas from POME.

Boiler sizing: for 10 TPH FFB and steam 0.6–1.0 t/t FFB → 6–10 t/h saturated steam; specify 8–12 t/h with 15–20% margin.

Pressure levels: gen. 20–25 bar(a) main → back-pressure turbine to 3–4 bar(g) for process; electricity co-generation 0.6–1.2 MW (site-dependent).

Heat recovery: economizer, air pre-heater, condensate/flash recovery to DA.

? Water Treatment & Utilities

BFP/boiler feed: raw → multimedia filtration → softener/RO (as required) → DA hotwell (105–120 °C).

Compressed air: 6–8 bar(g), dryers to −20 °C PDP; receivers sized for peak actuation.

Thermal oil/hot water loops for steady heating where steam not preferred.

Power distribution: MCCs (Motor Control Centers), smart VFDs, UPS for controls; lightning/earthing grid.

? Effluent & By-product Handling

POME (Palm Oil Mill Effluent): 0.6–1.0 m³/t FFB → cooling, anaerobic (UASB/CSTR) + aerobic polishing; biogas 15–28 m³/m³ POME (55–65% CH₄).

Sludge oil recovery via decanter; EFB composting/windrow systems with leachate control.

Ash & dust: cyclone/multicyclone + bag filter as required by local emissions code.

? Key Equipment – 10 TPH FFB Reference Class

Reception: truck tipper, grille pit, belt/chain feeders (VFD), 60–80 t weighbridge.

Sterilizers: horizontal batch (2–4 cages) or continuous; auto cycle, pressure safety valves, SIL-rated interlocks.

Threshers: 1–2 drums (N+1 optional), wear liners, EFB conveyor to yard/shredder.

Digesters: 2–3 vessels, steam jackets, 20–35 kW drives, level/temperature control.

Presses: twin-screw expellers with adjustable choke, dilution injection, press torque scan.

Clarification: screens → sand trap → feed heaters → decanter → disc-stack purifier → vacuum dryer.

Storage & Piping: steam-traced lines, ANSI flanges, API tanks with coils & insulation.

Kernel section: depericarper, ripple mills, hydrocyclones/air tables, dryers, silos.

Boiler island: 8–12 t/h biomass boiler, economizer, DA, condensate recovery, water treatment; back-pressure turbine-generator optional.

Automation: PLC/SCADA, historian dashboards (yield, energy), condition monitoring (vibration/temperature) on rotating kit.

HSE: fire detection/suppression (foam/water), LOTO, confined-space permits, pressure-vessel compliance; RSPO/ISO documentation support.

? Performance, Mass–Energy & Utilities

Throughput & Yields (indicative, per 10 TPH FFB)

CPO yield: 20–23% on FFB → 2.0–2.3 TPH CPO.

PK yield: 5–7% on FFB → 0.5–0.7 TPH kernel to PKO line.

By-products (typical on FFB): fiber 12–14%, shell 6–7%, EFB 20–23%.

Utility Intensities (per ton FFB) and Daily Loads (24 h)

Electricity: 12–20 kWh/t → 2.9–4.8 MWh/day at 240 t/d.

Steam: 0.6–1.0 t/t → 144–240 t/day.

Water: 0.5–1.5 m³/t → 120–360 m³/day (recycling minimized).

POME: 0.6–1.0 m³/t → 144–240 m³/day to ETP.

CPO Quality: Moisture ≤ 0.25%, impurities ≤ 0.25%, FFA minimized by sterilization discipline.

Values vary with FFB quality, fruit ripeness, integration level, and equipment selection.

? Control, Safety, QA/Traceability

Advanced controls: sterilization “recipes”, press torque/power trends, decanter vibration/temperature, purifier differential pressure, vacuum dryer moisture trending; real-time OEE.

Safety: guarded nip points, emergency stops, pressure relief, compliant platforms and handrails, hot-surface shielding.

QA/QC plan: inline sampling; FFA (hourly), DOBI (Deterioration of Bleachability Index) per batch/shift, moisture/impurities (Karl Fischer & gravimetric), sludge oil losses, tank settlement tests.

RSPO chain of custody: MB (Mass Balance) or SG (Segregated) with digital lot tracking.

? Layout, Civil, Integration

Compact gravity flow: sterilizer → thresher (upper level) → digesters/presses (mid-level) → clarification (lower).

Civil: reinforced floors for heavy rotating equipment; pits for sand traps/clarifiers; truck circulation & EFB yard drainage.

Noise & air: acoustic lagging of blowers; adequate ventilation in digestion/press halls; deodorization hoods where required.

Scalability: press & centrifuge N+1 blocks; boiler/turbine sized with future tie-in points.

? Environmental & Energy Integration

Boiler fuel balance: fiber + shell generally sufficient for steam self-sufficiency; shredded EFB and biogas add margins in wet season.

Biogas use: boiler co-fire or dedicated biogas boiler; flare as last resort; condensate/condensers for H₂S mitigation.

ETP: equalization → anaerobic (UASB/CSTR) → aerobic (facultative/MBR) → polishing; sludge dewatering by decanter/press.

Emissions: dust control (multicyclone/baghouse), stack monitoring; ash reuse in field (per agronomic plans).

? Commissioning & Ramp-Up (10-week plan from Mechanical Completion)

W1–W2: Mechanical completion, IO checks, dry runs; pressure tests; safety interlocks validation.

W3–W4: Boilers/steam system commissioning, hot oil/condensate loops, sterilizer water runs, functionals.

W5–W6: First fruit runs at reduced rate; tuning thresher/digester/press parameters; clarification balance.

W7–W8: Full-rate operation; purifier/vacuum dryer optimization; ETP biological start-up; operator certification.

W9–W10: Performance Test (throughput, yields, utilities, CPO specs); punch-list closeout; documentation handover.

Deliverables include PFDs (Process Flow Diagrams), P&IDs (Piping & Instrumentation Diagrams), GA layouts, utility balance, data sheets, FAT/SAT records, SOPs, maintenance plans, and training certificates.

? Spares, Training, O&M

Initial spares (12 months critical): press wear parts (worms/cages), ripple-mill beaters, purifier seals, decanter bearings, pump mechanical seals, screen panels, V-belts, instruments (T/P/level), VFD/PLC I/O.

Training program: operator & maintainer tracks (process theory, sterilizer discipline, centrifuge & purifier care, boiler firing, ETP biology, LOTO, confined space).

Preventive strategy: monthly condition checks, quarterly PMs, annual statutory inspections of pressure parts; vibration and oil-analysis for rotating equipment.

? Commercial Package (What We Deliver)

Engineering package: PFDs, P&IDs, GA, foundation loads, cable/pipe lists, cause-and-effect matrices.

Scope options: supply-only; supply + supervision; full EPC (Engineering, Procurement, Construction) with performance guarantees.

Financials: CAPEX/OPEX models, BoM, life-cycle cost, energy balance; ROI sensitivity to FFB quality, seasonality, and energy prices.

Compliance dossier: pressure vessel files, electrical/ATEX (where applicable), RSPO/ISO templates, environmental permits support.

✅ Investment Thesis

A 10 TPH RSPO-aligned palm oil mill with biomass CHP and robust clarification delivers bankable yields, low unit energy, and export-grade CPO quality. Integrated by-product valorization (fiber/shell/EFB/biogas) underpins utility self-sufficiency and mitigates fuel risk.

? Next steps for producers & investors

Request the site-specific financial model (yields, utilities, staffing, tariffs → ROI/IRR/payback).

Ask for preliminary technical layouts adapted to your plot and future expansion.

Schedule a technical–commercial session to finalize scope, guarantees, and delivery window.

? Contact us today to secure your comprehensive proposal and move from feasibility to first-oil with confidence.

- For more information:

? : Contact Us