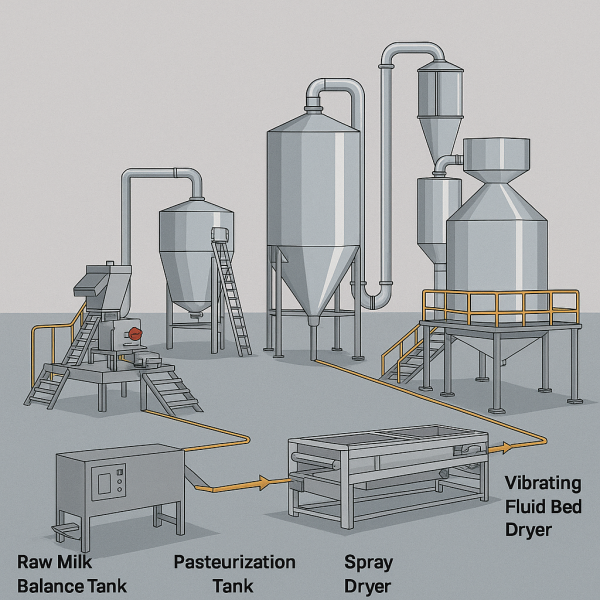

Complete 1000 Liters/H milk powder production line

Sector

TURNKEY FOOD INDUSTRY PROJECT ➠ COMPLETE MILK POWDER PRODUCTION LINE

Denomination or Username

NIRUDI - [Eco Sustainable Digital B2B - B2C ePlatform Tool]

Type of user

Size of the company

Description

- Detailed Machinery Description for Castor Oil Production (1000 Kg/H Extraction Line)

No. Flow No. Name Model Main Technical Parameters Unit QTY A — Milk reception unit 2 A-1 Milk pump 1T/H SUS304 stainless steel, pump lift is 24 m, mechanical seal PCS 1 3 A-2 Twin piping filter 1T/H Material-touch is SUS304 stainless steel, two pipe, stainless steel filter element 100 mesh PCS 1 4 A-3 Cyclone degassing machine 1T/H SUS304, tangent feed, bottom discharge PCS 1 5 A-4 Milk pump 1T/H SUS304 stainless steel, pump lift is 24 m, mechanical seal PCS 1 6 A-5 Electromagnetic Flow meter 1T/H SUS304, 4–20 mA signal output, pulse count PCS 1 7 A-6 Plate cooler 1T/H SUS304 stainless steel, one section, ΔT=16 °C, outlet milk temperature 4 °C PCS 1 Subtotal — A No. Flow No. Name Model/Capacity Main Technical Parameters Unit QTY B — Pre-pasteurization & storage unit 10 B-1 Milk storage tank 30000 L SUS304, 60 mm PU insulation, skirt, inclined bottom discharging, Miller jacket, closed side manhole, ladder, guardrail, digital thermometer, sampling valve, Germany JUMO temperature sensor, Ram beau static pressure sensor, CIP cleaning ball, breathing valve, lateral mixing/960 rpm PCS 2 11 Press Sensor SUS304, 4–20 mA signal output, range 0–1 bar PCS 2 12 Temperature Sensor PT100 SUS304, 4–20 mA signal output, range 0–200 °C PCS 2 13 B-2 Milk pump 1T/H SUS304 stainless steel, pump lift is 24 m, mechanical seal PCS 1 14 B-3 Plate pasteurizer 0.5T/H Material-touch SUS304 stainless steel, plate type; 5 °C inlet, 85 °C (15 s sterilize), 4 °C outlet; automatic temperature control with recorder; CIP cleaning; Spirax Sarco steam depressure & control system PCS 1 Subtotal — B No. Flow No. Name Model/Capacity Main Technical Parameters Unit QTY C — Concentrating unit 17 C-1 Falling film evaporator 300 L/H Full automatic control; SUS304 host material; carbon steel frame; four-effect falling film evaporation (6300 L/H capacity); Siemens PLC control; Italian Meisali sugar degree instrument; German GEA pneumatic valves; differential pressure liquid level transmitter; flavor recovery system set 1 18 C-2 Concentrated milk storage tank V=200 L SUS304; double-layer; conical head; top offset vertical mixing; sampling valve; adjustable legs; glass tube level gauge; union discharge valve set 1 19 C-3 Milk pump 1T/H SUS304 stainless steel; 24 m pump lift; mechanical seal PCS 1 20 C-4 High pressure pump 0.3T/H SUS304 material-contact parts; variable frequency speed control set 1 Subtotal — C No. Flow No. Name Model/Capacity Main Technical Parameters Unit QTY D — Spraying UNIT 23 D-1 Spray drying system 80 kg/H 1. Vertical type, top inlet/outlet pressure spray drying tower with integrated fluidized bed

2. Spirax Sarco steam control system, air heating system, blower, air filtration

3. Two-stage cyclone + whirlwind powder cartridge

4. Vibrating fluidized bed, screen, sub-powder, air delivery systemset 1 24 D-2 Powder warehouse 2M² SUS304 stainless steel, single layer set 1 Subtotal — D E — Water treatment system 27 E Water treatment system 1T/H Includes:

- 10 m³ water box

- Multi-media filter (silica medium)

- Activated carbon filter (shell carbon)

- Precision/cartridge filters

- 20T pure water tank

- Complete piping with pumps/valves

set 1 Subtotal — E No. Flow No. Name Model/Capacity Main Technical Parameters Unit QTY F — Full automatic CIP system 30 F Full-automatic CIP system IT Three tanks, single circulation:

- SUS304 double-layer insulated tanks

- Acid/alkali tanks with stirrers

- PLC touch screen control

- High/low liquid level alarm

- Spirax Sarco temperature control

- JUMO temperature sensors

- Conductivity/flow rate monitoring

- Shanghai YUAN progress pump (20T/H, 36 M lift, ABB motor)

- Plate heater for online warming

- 300 L SUS316L concentrated acid/alkali tanks

- USA imported pneumatic diaphragm pumps (2)

PCS 1 31 F-1 CIP return pump 30T/H SUS316L stainless steel, 24 m pump lift, mechanical seal PCS 1 32 F-2 CIP return pump 10T/H SUS316L stainless steel, 24 m pump lift, mechanical seal PCS 1 Subtotal — F No. Flow No. Name Model/Capacity Main Technical Parameters Unit QTY G — Packing unit 34 G-1 1 Kg bag packing machine 20 bags/minute Includes 1.4 m conveying belt and code printer PCS 1 Subtotal — G Total price for equipment H — Installation unit 38 H-1 Product piping system - CIP pipeline, processing pipeline, sewage pipeline

- All required valves/meters

- Complies with SMS standard

PCS 1 39 H-2 Power piping system Includes:

- Steam pipeline (carbon steel)

- Ice water pipeline (hot-dip galvanized)

- Tap water pipeline (hot-dip galvanized)

- Compressed air pipeline (carbon steel)

- All required valves/meters

Excludes pipe insulation. Buyer connects main pipes.

- About us

For more information: