From Field to Pharmacy: Unlock the Premium Value of Your Castor Seed Harvest

- From Field to Pharmacy: Unlock the Premium Value of Your Castor Seed Harvest

Your castor seed harvest holds a potential far beyond the commodity market. It is the raw material for one of the world's most versatile and in-demand industrial and cosmetic oils. The time has come to stop selling a raw ingredient and start manufacturing a high-value, finished product.

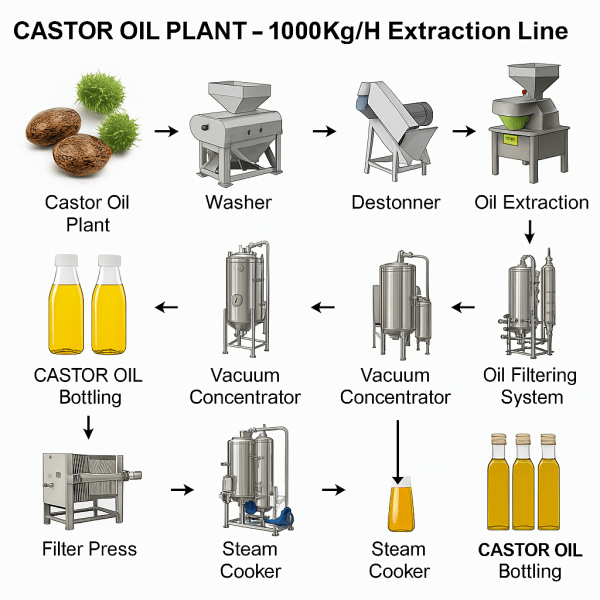

We present the complete, end-to-end 1000 Kg/H Castor Oil Extraction and Refining Line—a robust, turnkey solution engineered to transform your raw seeds into pure, refined, and market-ready castor oil, positioning you to capture premium prices in the pharmaceutical, cosmetic, and industrial sectors.

The Journey from Seed to Pure Oil: A Meticulously Engineered Process

Our fully integrated line ensures that every stage of production is optimized for yield, purity, and safety, resulting in a final product of exceptional quality.

Stage 1: The Foundation of Purity – Uncompromising Seed Preparation Excellence begins with immaculate raw material.

- High-Efficiency Washer: The process starts with a thorough cleaning in our industrial washer. High-pressure water sprays and mechanical action remove all dirt, dust, and field impurities from the castor seeds.

- Precision Destoner: The cleaned seeds are then passed through a Destoner. Using gravity and mechanical separation, this essential unit removes any stones, pebbles, or other heavy foreign matter, protecting downstream machinery and guaranteeing the purity of the seed stock.

Stage 2: The Core of Production – Safe and Maximum-Yield Extraction This is where the transformation into liquid gold begins, with a critical focus on both efficiency and safety.

- Precision Steam Cooker: Before extraction, the seeds are treated in a Steam Cooker. This vital step is twofold: it precisely heats the seeds to optimize the cell structure for maximum oil release during pressing, and crucially, it deactivates natural toxins present in the raw seeds, ensuring the resulting oil and byproducts are safe.

- High-Yield Oil Extraction Machine: The prepared seeds are then fed into our state-of-the-art Oil Extraction Machine. Whether utilizing high-pressure mechanical pressing or solvent extraction, this unit is engineered for maximum efficiency, ensuring you extract the highest possible volume of crude oil from your seeds.

Stage 3: The Pinnacle of Refinement – A Multi-Stage Purification Masterpiece Crude oil is just the beginning. Our advanced refining process elevates your product to premium grade.

- Multi-Stage Oil Filtering System: The raw oil first undergoes an initial filtration process to remove all solid seed residues and large impurities, achieving primary clarity.

- High-Efficiency Filter Press: For an even finer level of purity, the oil is then forced through a Filter Press. This system uses high pressure to push the oil through specialized filter plates, capturing even the smallest particulates and ensuring a brilliantly clear product.

- Proprietary Three-Stage Vacuum Concentration: This is the technological heart of our refining process and what guarantees a superior final product. The filtered oil is processed through a series of three Vacuum Concentrators. By gently heating the oil in a vacuum, we effectively remove moisture and volatile compounds without high temperatures that could degrade the oil. This method prevents oxidation, preserves the oil's chemical integrity, and results in a product with exceptional stability and a long shelf life.

Stage 4: The Final Touch – Retail-Ready Automated Bottling The final stage prepares your premium oil for the global market.

- Final Castor Oil Bottling Line: The fully refined, purified, and stabilized castor oil is transferred to the automated bottling line. This system ensures high-precision filling into bottles of your choice, followed by secure capping and labeling, delivering a professional, shelf-ready product for immediate distribution.

Your Strategic Business Advantage:

- Enter High-Value Markets: Transition from selling a low-margin agricultural commodity to marketing a high-demand ingredient for the cosmetic, pharmaceutical, and industrial sectors.

- Safety and Quality Assured: Our integrated Steam Cooker and advanced refining process guarantee a final product that is not only pure but also safe and compliant with industry standards.

- Maximum ROI: Engineered for high yield and efficiency, our 1000 Kg/H line is a powerful production asset designed for significant output and profitability.

- Complete Turnkey Solution: Eliminate the complexity and risk of sourcing individual machines. We provide a fully integrated, synchronized system designed for seamless operation.

The demand for high-quality, pure castor oil is unwavering. Don't just cultivate the seeds—create the solution. Contact us today to learn how our Castor Oil Production Line can revolutionize your business and unlock a new era of profitability.

- For more information:

? : Contact Us