High-Efficiency Turnkey Potato Chips Manufacturing Facility – 2 TPH Capacity

- ? High-Efficiency Turnkey Potato Chips Manufacturing Facility – 2 TPH Capacity

This proposal details a complete, state-of-the-art 2 Ton Per Hour (TPH) potato chips manufacturing plant. Delivered on a turnkey basis, this project is designed for maximum profitability and operational efficiency. It integrates advanced automation, rigorous quality control, and sustainable practices to produce premium snack products for a rapidly expanding global market. With a clear capital expenditure framework and compelling financial returns, this project represents a low-risk, high-opportunity investment in the lucrative snack food sector.

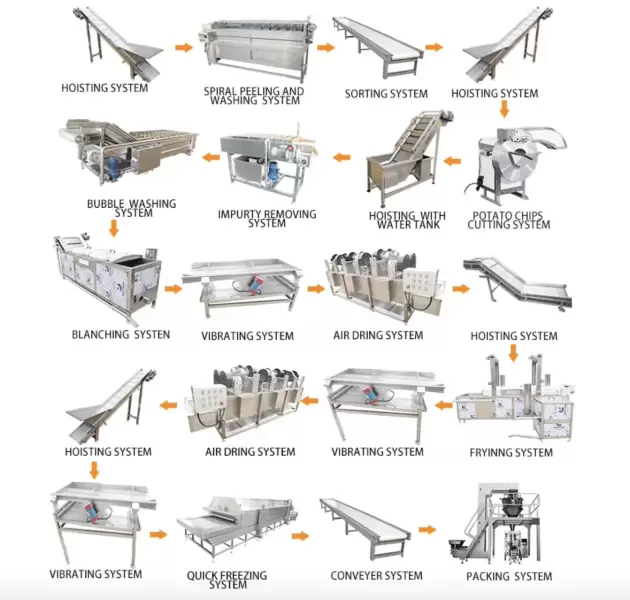

1.0 Detailed Process Flow & Equipment Specification

The line is engineered for continuous, high-throughput operation with minimal manual handling, ensuring product consistency and food safety.

1.1 Raw Material Reception & Pre-Storage: Incoming potatoes are unloaded via a tipper or conveyor into a Receiving Hopper. To minimize bruising, they are then transported via Water Flumes to a Pre-Cleaning Rotating Drum, which removes stones, soil, and other field debris before storing the potatoes in Ventilated Silos.

1.2 Washing & Peeling: Potatoes are uniformly fed into a High-Capacity Brush Washer. Cleaned potatoes then proceed to either an Abrasive or Steam Peeler. The Steam Peeling Upgrade Option is highly recommended as it significantly reduces peel loss (from ~15% to ~8-10%), saves water, and provides a smoother surface for consistent slicing.

1.3 Inspection & Sorting: Peeled potatoes are conveyed under High-Resolution Optical Sorters. These advanced cameras use AI to identify and eject defects such as green spots, rot, bruises, and remaining peel, which is critical for ensuring the final product's quality.

1.4 Slicing & Washing: Approved potatoes are sliced to a precise thickness (0.8mm - 1.8mm) by an Ultra-High-Speed Slicer equipped with hardened, laser-cut blades. Slices are then rinsed in a De-starching & Washing Drum to remove excess surface sugars and starch. This is a vital step for achieving a uniform golden color and preventing the chips from sticking together during frying.

1.5 Blanching (Optional but Recommended): Slices pass through a Hot Water or Steam Blancher. This step further removes sugars to control color, pre-firms the texture for a better crunch, and significantly reduces the potential for acrylamide formation, a key food safety concern.

1.6 Drying: A High-Velocity Air Dryer (de-watering shaker) removes surface moisture from the slices. This is essential for achieving oil economy, ensuring safety, and producing a crispy final product.

1.7 Frying: This is the core of the line. Slices are conveyed through a Continuous Multi-Zone Fryer with precision temperature control in each zone. Key features include automatic oil level regulation, continuous oil filtration, and indirect heating (via thermal oil or steam) for a clean, consistent product. An integrated Hot Oil Filtration System with paperless pre-coat filters continuously removes fines, extending oil life and maintaining product quality.

1.8 Dewatering & Seasoning: Fried chips pass over a Vibrating Dewatering Screen to drain excess oil, then move through a Seasoning Drum. This tumbler applies oil, salt, and powdered seasonings with pinpoint accuracy for uniform flavor coverage.

1.9 Cooling & Inspection: Chips are cooled on a Multi-Tier Cooling Conveyor to set their structure and crunch. A final Metal Detector and Checkweigher ensure product safety and weight compliance.

1.10 Primary & Secondary Packaging: Chips are fed into an Integrated Vertical Form-Fill-Seal (VFFS) Machine that creates bags from roll-stock film, fills them with a precise weight, flushes with inert gas (Nitrogen) for freshness, and seals them. Finished bags are then conveyed to an Automatic Case Packer and Palletizer.

2.0 Utility Consumption & Sustainability Features (Per Ton of Finished Product)

Utility Consumption Range Notes & Sustainable Practices Electricity 250 - 350 kWh Major loads are from slicers, fryer conveyors, and compressors. The system uses high-efficiency motors and Variable Frequency Drives (VFDs) as a standard. Thermal Energy 2.5 - 3.5 GJ Used for frying, blanching, and seasoning. Options include natural gas, LPG, or biomass boilers. Heat recovery systems are available to pre-heat process water or plant air. Process Water 4 - 6 m³ Used in fluming, washing, and blanching. A Water Recycling System can reduce fresh water usage by up to 70%. Compressed Air 15 - 25 Nm³ Powers pneumatic controls, optical sorters, and packaging machines. 3.0 Facility & Layout Requirements

The total building area is estimated at ~1,800 - 2,200 m². The layout is zoned to be GMP/HACCP Compliant:

Raw & Dry Goods Area: Unloading, and storage for potatoes, oil, seasoning, and packaging.

Wet Process Area: Washing, peeling, slicing, and blanching. This area is constructed with stainless steel, sloped floors, and floor drains.

Fried Process Area: Frying, seasoning, and cooling. This section features high-volume exhaust hoods and fire suppression systems.

Packaging Hall: A climate-controlled (low humidity) environment for VFFS machines, case packing, and palletizing. It uses positive air pressure to keep dust out.

Utilities Room: Houses the boiler, electrical panels, air compressors, and water treatment systems.

4.0 Capital Expenditure (CAPEX) Breakdown

Figures in USD, indicative for a complete turnkey project in a standard greenfield scenario.

Category Estimated Cost Details & Inclusions Process Equipment $1.4M - $2.5M All machinery from reception to palletizing, including automation (SCADA) and process control sensors. Utility Systems $300k - $700k Boiler, water treatment, electrical substation, compressed air, HVAC for packaging hall. Installation & Civil Works $200k - $500k Foundation, building modification, equipment erection, piping, wiring, insulation. Project Management & Commissioning $100k - $300k Detailed engineering, P&IDs, factory acceptance tests, shipping, on-site commissioning, and performance tests. Total Estimated CAPEX $2.0M - $4.0M The final quote depends on technology selections, the level of automation, and site-specific conditions. 5.0 Operating Expenditure (OPEX) Snapshot

Per ton of finished potato chips, excluding the cost of raw potatoes.

Cost Center Estimated Cost per Ton Notes Raw Materials (Excluding Potatoes) $400 - $700 Palm/Sunflower oil, seasonings, and packaging materials. This is the largest variable cost. Utilities $120 - $200 Highly dependent on local energy prices. Labor (3-shift operation) $80 - $150 Requires 8-12 operators per shift for line operations, quality control, and warehouse management. Maintenance & Spares $40 - $60 Based on a planned preventive maintenance program. Quality Control & Admin $50 - $90 Includes laboratory supplies, management, and overheads. Total Estimated OPEX per Ton $690 - $1,200 Yield is critical: 4.0 - 4.5 kg of raw potatoes typically yield 1 kg of finished chips. 6.0 Financial Model & Investment Rationale

Annual Production Capacity: ~4,000 tons (assuming 5,000 hours/year at 80% efficiency).

Revenue Assumptions: Wholesale price is highly variable by region and brand ($2,500 - $5,000/ton).

Gross Profit Margin: A margin of 40% - 50% is achievable with efficient operations and good yield management.

Net Profit Margin (EBITDA): 20% - 30% after accounting for full overhead, depreciation, and finance costs.

Return on Investment (ROI): >35% per annum.

Payback Period: 1.5 - 3 years, contingent on market penetration speed and operational efficiency.

7.0 Risk Mitigation & Project Support

Turnkey Responsibility: Single-point accountability for design, supply, installation, and commissioning eliminates interface risks.

Performance Guarantee: Contractual guarantees on key metrics: Throughput (2 TPH), Product Yield (<4.5:1 raw to finished), Oil Absorption (<36%), and Utility Consumption.

Comprehensive Training: A 3-phase program includes: 1) classroom training at our facility, 2) on-site commissioning training, and 3) an advanced troubleshooting and maintenance workshop.

Spare Parts Package: A recommended initial inventory of critical spares (slicer blades, fryer basket bands, V-belts, bearings, electrical components) ensures >90% plant availability.

Commissioning Timeline (7 Weeks):

Week 1-2: Mechanical completion, power-on, and dry runs.

Week 3-4: Wet runs with water and oil, calibration, and first product.

Week 5-6: Integrated continuous run, optimization, and quality tests.

Week 7: Operator training finalization, performance tests, and handover.

- For more information:

? : Contact Us