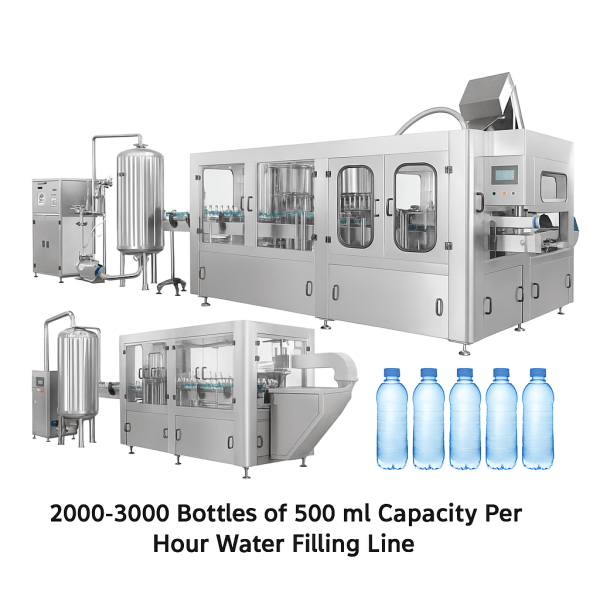

From Source to Shelf: Launch Your Premium Bottled Water Brand with Our Complete 3,000 BPH Filling Line

- From Source to Shelf: Launch Your Premium Bottled Water Brand with Our Complete 3,000 BPH Filling Line

Does your enterprise have access to a pure water source? It's time to stop seeing it as a simple resource and start seeing it for what it truly is: a lucrative opportunity to create a high-value, consumer-facing brand.

We present a comprehensive, turnkey Water Bottling Line, engineered for a capacity of 2,000-3,000 bottles per hour (500 ml). This is not just a collection of machines; it is a fully integrated, automated ecosystem designed to transform your raw water into a shelf-ready, premium product. Make the strategic leap from producer to brand owner and capture the full value of your natural assets.

The Journey of Every Drop: An End-to-End Solution for Uncompromising Quality

Our production line orchestrates a flawless journey from the empty bottle to the final retail pack, with every stage optimized for purity, efficiency, and brand integrity.

1. The Foundation of Trust: Uncompromising Purification & Sterilization Before a single drop is bottled, we ensure absolute purity.

- Water Treatment System: Your source water is elevated to crystal-clear perfection through a multi-stage purification powerhouse. It passes through sand and activated carbon filters, undergoes Reverse Osmosis (RO) to remove the finest impurities, and is then sanitized with both a UV Sterilizer and an Ozone Generator. This guarantees water that is not only safe but exceeds the highest quality standards.

- Bottle Washing Machine: Simultaneously, every empty bottle is prepared in a state-of-the-art washing station. Using powerful water jets, rotary brushes, and sanitizing agents, we ensure that each bottle is impeccably clean and sterile, ready to receive your pure water.

2. The Heart of Production: Flawless Filling & Sealing This is where speed meets precision. At the core of our line is a high-performance Monoblock Filling & Capping Machine.

- Precision Filling: In one continuous, automated process, bottles are conveyed into the filling chamber. Our gravity or pressure filling technology dispenses a precise 500 ml volume into each bottle, eliminating waste and ensuring consistency.

- Airtight Capping: Immediately after filling, the integrated Capping Machine applies and hermetically seals each bottle. Whether you choose screw caps or snap caps, the result is a perfectly sealed product, protected from contamination and leakage, preserving its freshness and purity.

3. The Face of Your Brand: Perfect Labeling & Packaging With the product secured, we create its shelf appeal.

- High-Speed Labeling Machine: Bottles move seamlessly to the labeling station, where your brand identity comes to life. Our machine accurately applies self-adhesive or shrink-sleeve labels at full line speed, ensuring a professional, eye-catching finish.

- Retail-Ready Packaging Machine: The final step is preparing your product for distribution. Our system automatically groups the labeled bottles and packages them using shrink-wrapping or carton packing, creating durable, attractive multipacks ready for pallets and store shelves.

4. The Brain of the Operation: Intelligent & Automated Control The entire line is orchestrated by a central nervous system that guarantees efficiency and quality.

- Integrated Conveyor System: A network of stainless steel conveyors moves bottles flawlessly between each station. With adjustable speeds and intelligent buffering zones, the system maintains a smooth, continuous flow, preventing bottlenecks and maximizing throughput.

- Vigilant Quality Control: Strategically placed inspection stations act as your 24/7 quality assurance team. Using advanced vision inspection, weight checkers, and metal detectors, the system automatically identifies and rejects any imperfections—such as underfilled bottles, improper caps, or contaminants—ensuring that only perfect products reach your customers.

- Centralized PLC Control Panel: The entire line is managed from a user-friendly HMI (Human-Machine Interface). From this single point, your operator can monitor production, adjust settings, and view real-time data, putting complete control at their fingertips. Integrated safety interlocks and emergency stops ensure a secure operating environment.

Your Strategic Advantage:

- Turnkey Solution: Eliminate the guesswork and complexity. We provide a complete, pre-integrated line where every component is designed to work in perfect harmony.

- Engineered for Profitability: With high automation, low waste, and efficient operation, this line is designed to deliver a rapid return on investment.

- Unwavering Quality Assurance: From water purification to final inspection, build consumer trust with a product that is consistently safe, pure, and professional.

- Market-Ready Capacity: A production speed of 2,000-3,000 BPH positions you as a serious player, capable of supplying regional distributors and major retailers.

The market for pure, bottled water is expanding. It's time to claim your share. Contact us today for a personalized consultation and let's map out your journey from a natural source to a successful brand.

- For more information:

? : Contact Us