Turnkey Cassava Starch Production Plant – 5 TPH Capacity

- ? Turnkey Cassava Starch Production Plant – 5 TPH Capacity

1) Process & Equipment (fit-for-purpose, stainless steel contact parts)

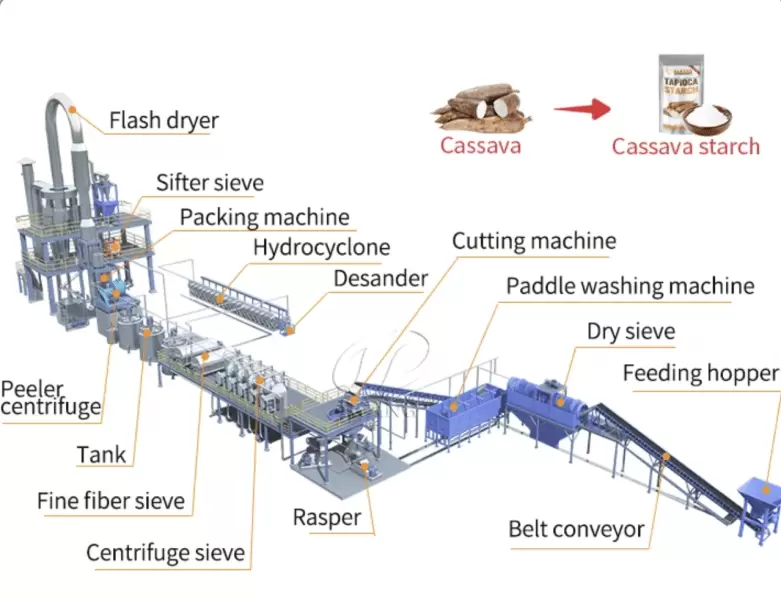

Raw Cassava Reception & Cleaning

Tippers, belt/roller conveyors, dry pre-cleaner (stone trap, bar screen), wet flume to cushion tubers.

Goal: remove soil/stones early to protect downstream pumps/raspers.

Washing & Inspection

Rotary drum/brush washer with high-impact spray bars (closed-loop water).

Manual or camera-assisted inspection table to reject rot/woody pieces.

Size Reduction (Rasping)

High-speed rasper (stator/rotor with replaceable tungsten blades), typical specific power 30–55 kWh/t starch.

Purpose: liberate starch granules from parenchyma cells; maximize extraction.

Pulp Handling & Primary Separation

Fiber screeners / rotary sieves (0.15–0.45 mm), pulp pumps, desanding cyclone to protect cyclones.

Target: coarse fiber removal before fine purification.

Hydrocyclone Purification Train

18–24 stage multi-cyclone system: concentration, dilution, washing, and clarification loops.

Outcomes: ash, pigments, proteins down; whiteness (L*) > 92 achievable for food grade.

Dewatering

Peeler centrifuge or belt press to 36–42% moisture (wet cake).

Optional decanter centrifuge for overflow recovery and water polishing.

Drying

Flash/ring dryer (indirect gas, thermal oil, or steam heat exchanger). Inlet 180–240 °C; outlet 80–95 °C.

Discharge moisture ≤ 12–13%; integrated cyclones + bag filter (ATEX-conscious dust handling).

Cooling, Milling & Sifting

Ambient or chilled air cooler → pin mill / hammer mill (if required) → vibratory sifter 120–200 mesh to set particle size distribution.

Packing & Palletizing

Automatic bagging 25 kg & FIBCs (1 t), checkweigher, metal detector, printer/QR traceability, robotic or conventional palletizer.

Automation

PLC/SCADA recipes, mass-balance dashboard, OEE; VFDs on fans/pumps; historian for utilities and quality.

2) Yield & Mass Balance (typical ranges)

Fresh cassava at 65–70% moisture contains 18–30% native starch (variety/season dependent).

Raw roots → starch ratio: 3.2–4.5 : 1.

Reference case (5 TPH starch): feed 16–23 TPH fresh roots.

Product specs: Moisture ≤ 13%, Ash ≤ 0.2%, pH 5.0–7.0, SO₂ ≤ 50 ppm (if used), micro per food-grade limits.

3) Utility Balance (per ton of starch, excluding raw cassava)

Electricity: 120–220 kWh/t (rasper, cyclones pumps, peeler centrifuge, fans).

Thermal energy: 1.0–1.6 GJ/t (flash/ring dryer; with heat recovery on exhaust).

Process water: 3–7 m³/t (with 70%+ reduction via counter-current washing & recycling).

Compressed air: 0.25–0.45 m³/min at 6–8 bar (actuators, valves, packers).

Steam (if used): 0.2–0.35 t/t starch for heating/CIP depending on dryer type.

Sustainability knobs

Effluent treatment: fiber trap → DAF/anaerobic digester; biogas can offset 15–30% dryer fuel.

Heat recovery: dryer exhaust → air/water preheat; VFDs on large fans.

4) Facility & Plot Plan (GMP/HACCP zoning)

Total building: ~6,000–8,500 m² (for 5 TPH starch output).

Zones:

Raw & Wet Zone: reception, washing, rasping, primary sieving (wet floors, drainage).

Purification Zone: hydrocyclones, tanks, CIP skids (hygienic segregation).

Dry Zone: dewatering, dryer, milling, sifting (dust control, ATEX).

Packing Hall: climate control, positive pressure, low RH.

Utilities & Labs: boiler/thermal oil, compressors, water treatment, QA/QC.

Warehousing & Dispatch: raw bags, finished pallets, forklift lanes.

5) CAPEX & OPEX (expanded)

CAPEX (USD) – order of magnitude, turnkey greenfield, 5 TPH starch output

Process equipment & automation: $4.0–8.2 M

Utilities (thermal, air, water, ETP/biogas): $1.1–2.2 M

Installation & civils (MEP, foundations, insulation): $0.9–2.0 M

Engineering, QA/validation, commissioning, spares, training: $0.6–1.1 M

Total: $7.0–14.5 M (scope, geography, and vendor mix drive variance)

OPEX (per ton of starch, excluding roots)

Energy (power + fuel): $18–35

Water & effluent: $3–8

Chemicals/consumables (CIP, antiscalant, filter media): $6–12

Labor (2–3 shifts, 30–45 staff total): $12–20

Maintenance & spares: $10–18

Packaging/overheads/QA: $11–27

Total OPEX: $60–120 per ton of starch

Raw cassava cost sensitivity (illustrative)

At 4.0:1 ratio and $70/t roots → $280/t starch raw-material cost.

Delivered cost target: $340–400/t (roots + OPEX) before SG&A and margin.

6) Spare Parts & Reliability Program

Critical spares (12–18 months): rasper blades/rotor sleeves, pump seals, hydrocyclone cones/liners (ceramic/PU), peeler screens, rotary valves, bag filter media, bearings, VFDs, PLC I/O modules, sensors (T/P/level), sifter screens, gaskets.

Uptime target: >92% with quarterly PMs; recommended CMMS (Computerized Maintenance Management System) and condition monitoring on fans/pumps.

7) Quality Management & Compliance

Standards: HACCP, ISO 22000/9001; food-contact MOC certificates.

In-line/at-line tests: moisture (NIR), whiteness (L*), ash, sieve analysis, microbial plate counts, viscosity (Brookfield for food grade).

Traceability: ERP/SCADA lot genealogy from farm gate to pallet.

8) Commissioning Timeline (proven 10-week roadmap from mechanical completion)

W1–W2: Mechanical completion, IO checks, dry runs, safety interlocks.

W3–W4: Water runs, CIP validation, pumps/valves tuning, cyclone balance.

W5–W6: First starch with conservative rates; dryer profiling; quality to spec.

W7–W8: Ramp to nameplate 5 TPH; utilities baselining; operator assessments.

W9–W10: Performance guarantee (yield/consumption/quality), documentation handover, spares audit.

Deliverables: PFDs/P&IDs, as-builts, manuals, validated SOPs/CIP, HACCP plan templates, calibration files, training certificates, warranty & performance certificates.

9) Options & Growth Path

Modified starch module (acid/oxidized/cationic) for paper/textile markets.

Biogas-to-steam upgrade to cut fossil fuel; solar thermal preheat on dryer air.

Fiber/pulp valorization: feed, biomaterials, or pellet fuel.

Chilled packing hall for premium food-grade whiteness stability.

10) Business Case & Market

Global cassava starch market projected ~$99.91 B by 2032; resilient demand across food and industrial sectors.

Producers gain market access and price premiums with consistent whiteness/specs.

Investors target gross margin > 42% and net margin > 26% when roots supply and energy are optimized.

Ready to quantify your site-specific returns?

Request the interactive financial model (roots price, utilities, labor, selling price → ROI/IRR/payback).

Ask for a preliminary technical layout matched to your plot and utility envelope.

Schedule a technical–commercial review to lock scope, delivery window, and guarantees.

This turnkey plant is not just machinery—it is a repeatable, bankable platform for sustainable export growth.

- For more information:

? : Contact Us