Unlock Perpetual Value: Transform 1000 Liters of Liquid Milk into Stable, High-Demand Powder Every Hour

- Unlock Perpetual Value: Transform 1000 Liters of Liquid Milk into Stable, High-Demand Powder Every Hour

Are you seeking to transcend the limitations of the fresh milk market? The challenges of short shelf life, price volatility, and complex cold-chain logistics can cap your profitability. But what if you could transform your perishable liquid asset into a stable, globally-marketable, high-value ingredient?

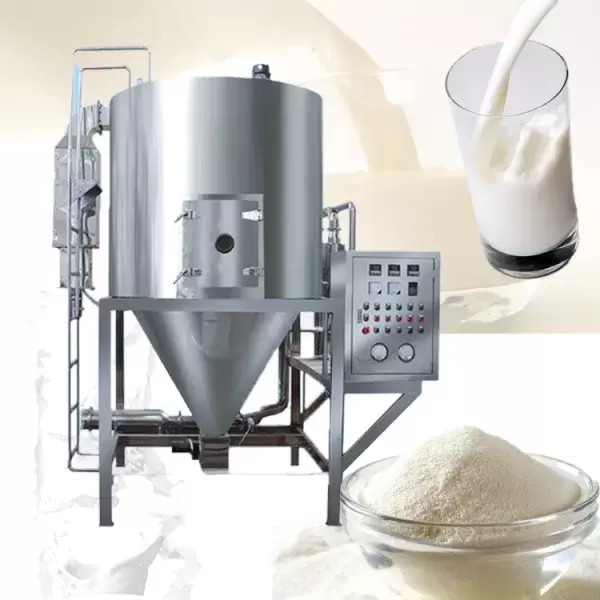

We present the Complete 1000 L/H Milk Powder Production Line—a fully integrated, end-to-end ecosystem engineered to convert your fresh milk into premium powder. This is not just a production line; it is your strategic leap from being a local supplier to a global player.

The Journey from Pasture to Powder: A Symphony of Precision Engineering

Our system meticulously guides your milk through a transformative journey, with every stage optimized for quality, efficiency, and the preservation of nutritional integrity.

Stage 1: The Foundation of Quality – Flawless Reception & Preparation Perfection begins the moment your milk arrives.

- Pristine Intake: The process starts with a Twin Piping Filter (100 mesh) that immediately captures any impurities.

- Enhanced Stability: The milk then flows into a Cyclone Degassing Machine, which uses tangential force to remove dissolved air. This crucial step reduces oxidation and enhances the stability of the final product.

- Rapid Preservation: A high-efficiency Plate Cooler instantly drops the milk's temperature to a safe 4°C, locking in freshness and arresting bacterial growth before it can begin. An Electromagnetic Flow Meter ensures every liter is precisely accounted for.

Stage 2: The Guardian of Freshness – Intelligent Storage & Pasteurization We protect your milk's quality with uncompromising technology.

- Smart Storage: Your milk is held in two massive 30,000-liter storage tanks, which are more than just containers. They are technological guardians, featuring 60mm PU insulation, Miller jacket cooling, and a suite of high-end sensors, including German JUMO temperature sensors and Ram beau static pressure sensors for precise monitoring.

- Precision Pasteurization: The milk undergoes pasteurization in a state-of-the-art Plate Pasteurizer. With a world-class Spirax Sarco steam control system, it executes a perfect High-Temperature Short-Time (HTST) process—heating to 85°C for exactly 15 seconds—to ensure safety while protecting the milk's delicate flavor and nutritional profile.

Stage 3: The Art of Concentration – Gentle Power, Maximum Potency This is where the transformation intensifies. Our system concentrates the milk solids without compromising quality.

- The Four-Effect Falling Film Evaporator: This is the technological heart of the line. Fully automated by a Siemens PLC, this four-effect evaporator is a masterpiece of efficiency, gently removing water under vacuum. It is equipped with world-class components, including an Italian Meisali sugar degree instrument for real-time solid measurement and German GEA pneumatic valves for flawless control. Crucially, it includes a flavor recovery system, ensuring the final powder retains the authentic, rich taste of fresh milk.

Stage 4: The Alchemical Transformation – The Pinnacle of Spray Drying The concentrated milk is now ready for its final metamorphosis.

- Advanced Spray Drying System: In a towering vertical spray dryer, the concentrate is atomized into a fine mist and meets a precisely heated current of air. The liquid evaporates in an instant, leaving behind fine, consistent milk powder. The system features an integrated vibrating fluidized bed for final drying and cooling, ensuring optimal powder quality and solubility. The powder is then collected via a two-stage cyclone system, maximizing yield and efficiency.

The Unseen Heroes: The Pillars of Your Operation

A world-class production line is supported by world-class infrastructure.

- Absolute Purity Assured: A complete 1T/H Water Treatment System—including multi-media, activated carbon, and precision filters—provides ultra-pure water for all processes, a non-negotiable for premium food production.

- Intelligent, Automated Hygiene: Our Fully-Automatic Clean-In-Place (CIP) System is the brain behind your plant's hygiene. Controlled by a PLC touch screen and equipped with premium Spirax Sarco and JUMO components, it automates the entire cleaning cycle for tanks and pipelines. It monitors conductivity and flow rates to guarantee a perfect, repeatable clean every single time, saving water, energy, and labor while ensuring absolute food safety.

- From Powder to Product: The line is completed with a 1 Kg Bag Packing Machine, turning your bulk powder into a retail-ready product at a rate of 20 bags per minute.

- Seamless Integration: We provide the entire product and power piping system, built to SMS standards, ensuring a professional, turnkey installation.

Your Strategic Advantage:

- Break Free from Perishability: Convert a product with a shelf life of days into one that lasts for months or years.

- Access Global Markets: Powdered milk is a globally traded commodity, opening doors to export and B2B ingredient markets you could never reach with fresh milk.

- Uncompromising Quality: With premium components from Siemens, GEA, and Spirax Sarco, you are investing in reliability, precision, and a consistently superior final product.

- Turnkey Efficiency: From milk reception to the final packed bag, this is a fully integrated, automated solution designed for high output and optimal resource management.

Stop selling a commodity. Start building a global food ingredient brand.

Contact us today to explore how this complete milk powder production line can be the foundation of your enterprise's future growth and profitability.

- For more information:

? : Contact Us