Compact 304 Stainless Steel Automatic Poultry Slaughter Line (300-3000 BPH) – "Plug & Play" No-Installation Design

38.310,00 €

Availability:

In stock

Out of stock

Short Description

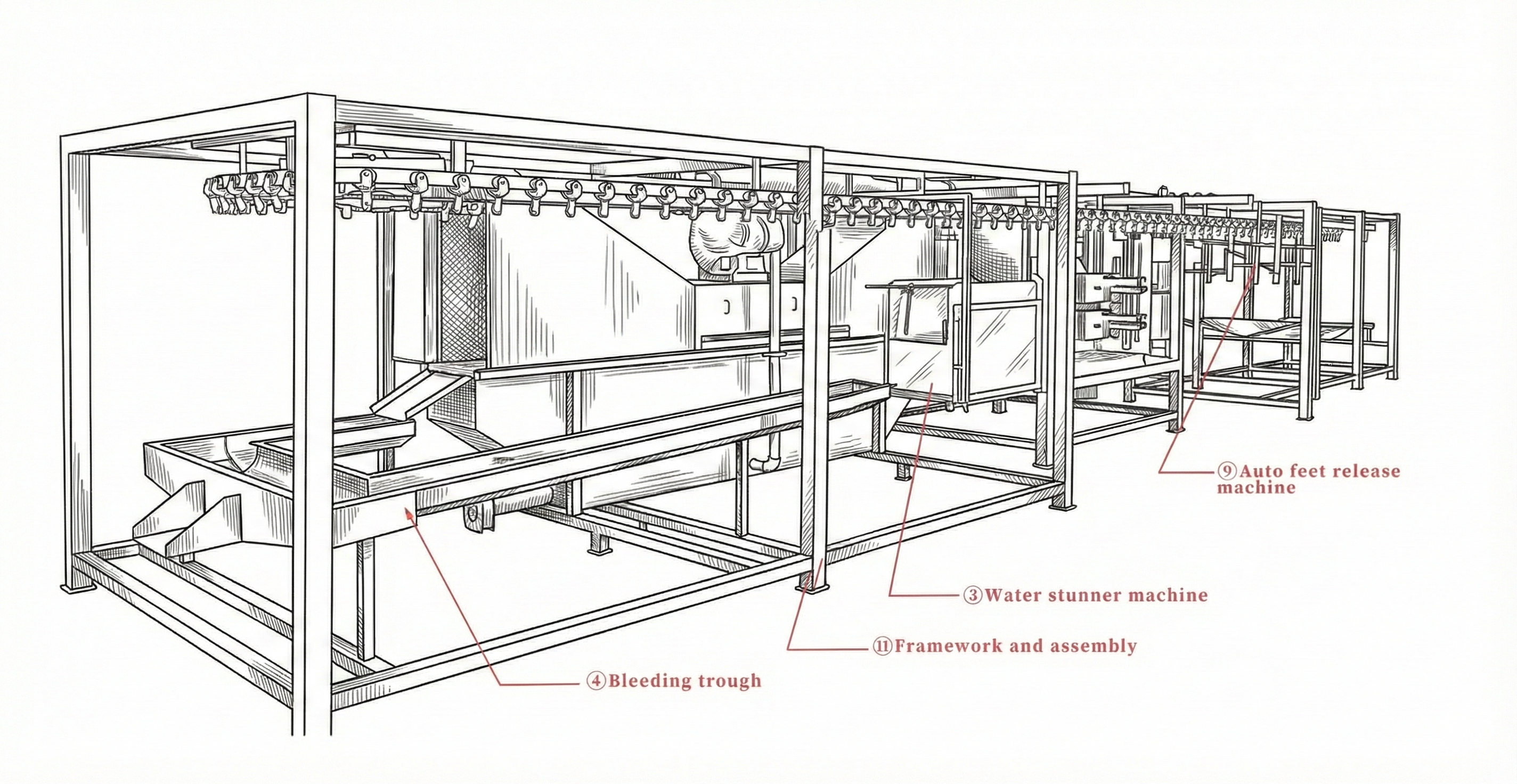

This fully integrated, compact slaughtering line is designed for small to medium-sized agri-food processing enterprises. Engineered with a "no installation required" philosophy, the system is mounted on a unified, high-strength stainless steel framework, allowing for rapid deployment and easy mobility

Sector

TURNKEY FOOD INDUSTRY PROJECT » COMPLETE SLAUGHTERHOUSE PRODUCTION LINE

Product Description

- Product Details & Technical Specifications

1. Key Technical Specifications

- Processing Capacity: Optimized for 500–1,000 birds per hour (BPH), with scalability from 300 up to 3,000 BPH via speed adjustment.

- Target Livestock: Broilers/Chickens (Live weight: 1.5kg ~ 5kg).

- Material Construction: Premium Food-Grade 304 Stainless Steel (rust/corrosion-resistant, hard, and durable).

- Total Power Consumption: 27 KW.

- Voltage: 380V, 50Hz, 3-Phase (Customizable to local country standards).

- Water Consumption: Approx. 2kg per bird.

- Installation Type: Integrated frame design; no on-site installation required.

- Warranty: 72-month quality warranty on the main framework.

2. Process Configuration & Components

- Conveyor & Hanging System:

- Features a stainless steel T-type orbit (50 x50 x4mm) with nylon wheels for noise reduction.

- Transfer speed is approximately 1.27 m/min (adjustable) with a hanger spacing of 152.4 mm.

- Stunning & Bleeding:

- Water Stunner (SDM-0.8M): Includes an adjustable voltage plastic electric groove and a stainless steel frame. Note: Halal configurations do not require stunning.

- Bleeding Trough: A 3200x1000x700 mm stainless steel sink ensures sanitary blood collection.

- Scalding System:

- Electric-Blowing Scalder: Uses an air-blower mechanical stirring system to ensure uniform water temperature (58ºC - 61ºC) and thorough feather preparation.

- Features automatic water level and temperature control.

- Defeathering (Plucking):

- Conventional Plucking Machine (ALT-4x8): Equipped with four correspondent stainless steel boxes and 4 sets of independent belt drives (1.1kw/set).

- Uses nylon defeathering plates and bars to ensure 0 damage to the carcass.

- Evisceration & Processing:

- Includes a specialized Head Puller, Automatic Foot Cutter, and Auto Shackle Release machine for streamlined processing.

- Visceral Trough: A stainless steel station (2400 x800x 800 mm) with spray pipes for manual evisceration and hygiene maintenance.

- Chilling:

- Screw Pre-Chiller: Reduces carcass temperature to 4ºC-10ºC within 30–40 minutes using cold water immersion.

3. Operational Advantages

- Plug-and-Play Mobility: The equipment fits into a 40HQ container and requires no complex installation, saving significant setup costs and time.

- Hygiene & Safety: Manufactured under ISO9001 and 6S management standards using 304 stainless steel. Includes emergency stops and overload protection for operator safety.

- High Efficiency: The automatic control system allows for speed adjustments, potentially increasing capacity by over 200 BPH while saving energy.

- Customization: The line supports additions or removals of devices (e.g., for Islamic slaughter requirements) and voltage customization for global compatibilit

- For more information:

Corregir este código para que bulleted list todo este alineado: " "