10 TPH multi-oilseed plant ready for East Africa

- 10 TPH multi-oilseed plant ready for East Africa

? Project overview and basis.

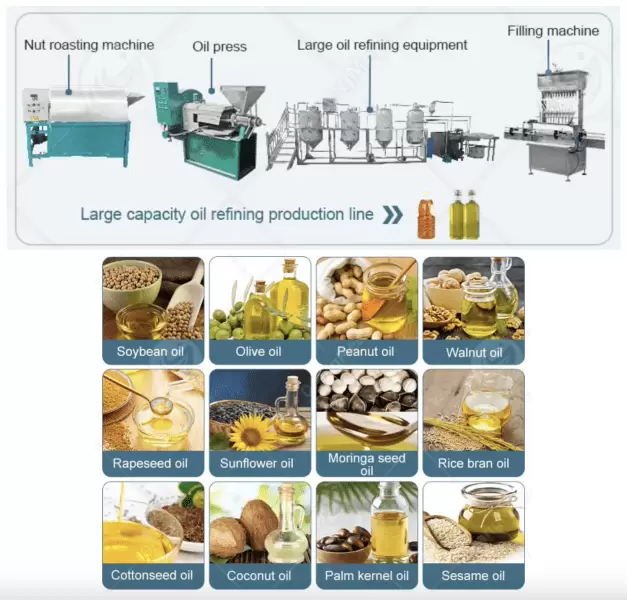

A 10 TPH (tons per hour) multi-oilseed line for East Africa is engineered to process the raw materials shown—soybean, olive, peanut, walnut, rapeseed, sunflower, moringa seed, rice bran, cottonseed, coconut, palm kernel and sesame—using a biomass-fired boiler for steam and grid electricity for drives and controls. Target packed-oil specifications are M&I (Moisture and Impurities) ≤0.10 %, FFA (Free Fatty Acids, as oleic) ≤0.10 %, PV (Peroxide Value) ≤3 meq O₂/kg and clear sensory after deodorization, with optional RBD (Refined, Bleached and Deodorized) finishing and winterization where required.

? Seed preparation aligned to each crop.

Cleaning, destoning and magnetic protection are followed by cracking, conditioning and flaking for soybean, rapeseed, sunflower and cottonseed to maximize cell rupture; controlled roasting for peanut, sesame, walnut and moringa seed reduces viscosity and lifts press yield; olive fruit passes a washer and crusher to a temperature-controlled malaxer to protect phenolics and FFA (Free Fatty Acids); coconut (copra) and palm kernel are cut, dried and fed to high-pressure expellers; rice bran is stabilized immediately by extrusion or parboiling to deactivate lipase before pressing or extraction.

?️ Pressing and optional solvent extraction.

Heavy-duty screw expellers sized for 10 TPH (tons per hour) provide primary oil recovery with choke regulation, dilution injection and shaft-torque monitoring; high-oil crops (peanut, sesame, coconut, palm kernel, moringa and olive paste) typically meet yield targets by pressing, while low-to-medium-oil seeds (soybean, sunflower, rapeseed, cottonseed and stabilized rice bran) route press cake to a continuous extractor, with miscella recovery and a DTDC (Desolventizer-Toaster-Dryer-Cooler) delivering low-residual-solvent meal.

? Crude-oil clarification and storage.

Hot crude from presses or separators passes vibrating screens and a sand-trap tank, then high-speed disc centrifuges remove gums and sludge; shell-and-tube heaters condition viscosity before insulated crude-oil tanks with heating coils and nitrogen blanketing minimize oxidation ahead of refining.

? Refining trains tailored by oil type.

Non-lauric seed oils (soybean, rapeseed, sunflower, cottonseed, peanut, sesame, moringa and rice-bran oils) undergo water or enzymatic degumming to reach phosphorus <10 ppm, caustic neutralization to reduce AV (Acid Value) and soaps, bleaching with natural adsorbents to reduce color and PV (Peroxide Value), dewaxing or winterization for waxy oils such as sunflower and rice-bran, and vacuum deodorization to ensure low odor and low 3-MCPD (3-Monochloropropane-1,2-diol) and GE (Glycidyl Esters) precursors; lauric oils (coconut and palm kernel) favor physical refining with steam-stripping and dry fractionation into stearin and olein.

? Utilities and energy concept.

Steam is generated by a water-tube boiler at ~20 barg (bar gauge) and reduced via PRV (Pressure Reducing Valve) stations to 3–4 barg (bar gauge) for process users, firing a sustainable blend of hulls, husks, shells, fiber, meal fines and local wood chips; electrical power from the grid feeds MCCs (Motor Control Centers) and VFDs (Variable Frequency Drives) under PLC/SCADA (Programmable Logic Controller/Supervisory Control and Data Acquisition) with UPS backup for critical instrumentation; water treatment provides soft and hot water plus validated CIP (Clean-in-Place) circuits, and the ETP (Effluent Treatment Plant) neutralizes soapstock wash waters and bleaching-earth filtrates with acid-oil recovery for by-product sales.

?️ Fit-for-purpose equipment set.

The front end comprises cleaners, destoners, magnets, dehullers, crackers, conditioners and flakers matched to crop; thermal units include roasters or malaxers as applicable; pressing uses twin expellers in parallel for availability; extraction, where installed, uses a continuous loop or rotary extractor with solvent recovery; clarification integrates disc centrifuges and pressure filters; refining combines degumming, neutralization, washing, bleaching, winterization and deodorization with a high-vacuum system; fractionation is included for lauric oils; packaging includes refined-oil tanks, inline filtration and multi-head filling-and-capping; the utility block houses the boiler, deaerator, BW (Boiler Water) and condensate tanks, air compressors and cooling water; the electrical room contains MCCs (Motor Control Centers), VFDs (Variable Frequency Drives) and PLC/SCADA (Programmable Logic Controller/Supervisory Control and Data Acquisition).

? Utility balance and yields for permitting and budgeting.

Typical averages at 10 TPH (tons per hour) mixed seeds are steam 0.4–0.8 t steam per ton of seed (4–8 t/h, tons per hour), electricity 25–50 kWh/t (kilowatt-hours per ton) with a 250–500 kW (kilowatt) operating band and a 630 kVA (kilovolt-ampere) transformer allowance, water 0.5–1.5 m³/t (cubic meters per ton) or 5–15 m³/h (cubic meters per hour); indicative refined-oil yields are soybean 17–19 %, sunflower 38–42 %, rapeseed 38–42 %, peanut 42–48 %, sesame 44–50 %, moringa 34–38 %, rice-bran 15–20 % after stabilization, coconut 60–65 % (copra) and palm kernel 45–50 %, with meal meeting feed specifications post DTDC (Desolventizer-Toaster-Dryer-Cooler).

? Plot-plan concept optimized for East Africa.

Gravity-friendly levels place intake and silos windward, preparation and conditioning on mezzanine, pressing and extraction on the main floor, refining and winterization adjacent with short heated pipe runs, tank farm and hygienic filling downstream, utilities on the lee side for natural draft, and maintenance, laboratory and administration at the secure perimeter; a compact 0.8–1.2 ha (hectares) under roof within a 1.5–2.0 ha (hectares) site leaves space for biomass yard and future doubling.

? Phased CAPEX and operating picture.

A press-centric refining and filling configuration typically lands at USD (United States dollars) 4.5–6.5 M including utilities and installation; the full configuration with solvent extraction, DTDC (Desolventizer-Toaster-Dryer-Cooler), dewaxing/winterization and deodorization typically ranges USD 7.5–11.0 M depending on import logistics; expected OPEX (Operating Expenditure) excluding seed is 12–25 USD/t with power 25–50 kWh/t (kilowatt-hours per ton), steam 0.4–0.8 t/t, bleaching earth 0.4–1.0 % on oil and routine chemicals by titration.

?️ Automation, safety and food quality.

The line runs on recipe-based setpoints in PLC/SCADA (Programmable Logic Controller/Supervisory Control and Data Acquisition) with interlocked E-stops (Emergency Stops), HSE (Health, Safety and Environment) platforms and guarding, LOTO (Lockout-Tagout) procedures, inline metal detection, allergen changeover SOPs (Standard Operating Procedures), QA/QC (Quality Assurance/Quality Control) sampling and validated CIP (Clean-in-Place) circuits.

? Spare-parts package for availability.

Start-up stock includes expeller worms, cage bars, bearings and seals; press and miscella pump mechanical seals; centrifuge bowl seals and gaskets; pressure-filter elements and cloth; roaster or malaxer gearmotor seal kits; refinery valve soft-seat kits; instrumentation spares—RTDs (Resistance Temperature Detectors) and DP (Differential Pressure) transmitters; electrical spares—VFD (Variable Frequency Drive) power modules and MCC (Motor Control Center) contactors and relays; the 12–24-month layer adds extractor chain and flights, DTDC (Desolventizer-Toaster-Dryer-Cooler) trays and valves, deodorizer ejector nozzles and a rotating spare purifier.

? Training plan focused on operators.

Weeks 1–2 cover process fundamentals, HSE (Health, Safety and Environment), LOTO (Lockout-Tagout), specifications (FFA (Free Fatty Acids), M&I (Moisture and Impurities), PV (Peroxide Value), AV (Acid Value)), utilities and SOPs (Standard Operating Procedures); Weeks 3–6 deliver coached operations for start-ups, shutdowns, alarm response, press-torque optimization, extractor and DTDC (Desolventizer-Toaster-Dryer-Cooler) balancing, centrifuge and deodorizer tuning, lab sampling and sanitation; Week 7 closes with written and practical assessments and work-area certification.

? Commissioning timeline adapted to your schedule.

Pre-commissioning over two weeks completes loop checks, instrument calibration, motor rotation, system flushing and boiler hydro; cold commissioning over one to two weeks performs dry material and water runs proving interlocks, conveyors, presses, extractor solvent loops, refinery washers and vacuum; hot commissioning over one to two weeks brings steam on, stabilizes conditioners, presses and extractor, sets degumming and neutralization targets, tunes bleaching and deodorization and validates winterization and fractionation; a one-week performance test confirms capacity, yields and packed-oil quality against KPIs (Key Performance Indicators) before handover and a coached ramp-up to full 10 TPH (tons per hour).

? What you receive and how to proceed.

The deliverable pack includes PFDs (Process Flow Diagrams), P&IDs (Piping and Instrumentation Diagrams), an I/O list (Input/Output), datasheets, a 2-D GA (General Arrangement) and utility balance together with operating manuals, SOPs (Standard Operating Procedures), maintenance plans and commissioning/SAT (Site Acceptance Test) protocols.

Share your first-wave crop mix, desired packaging sizes and any export standards and I will return a crop-specific equipment schedule, a dated Gantt and a phased CAPEX/OPEX (Capital Expenditure/Operating Expenditure) pro-forma tailored to your East Africa site.

- For more information:

? : Contact Us