Buyer-ready package for a 10 TPH Palm Oil Production Line, with biomass boiler (fiber/shell/EFB) and grid power.

- Buyer-ready package for a 10 TPH Palm Oil Production Line in Burundi, with biomass boiler (fiber/shell/EFB) and grid power.

Basis of Design

? Location: Central Africa (landlocked logistics, tropical climate; design for robust water/solids handling and high uptime).

⚙️ Capacity: 10 metric tons FFB/h (Fresh Fruit Bunches per hour; continuous duty).

(Units note used throughout: t = metric ton; h = hour; t/h = tons per hour; m³/h = cubic meters per hour; m³/d = cubic meters per day; kWh = kilowatt-hour; kW = kilowatt; kVA = kilovolt-ampere; USD = United States dollars; ha = hectares.)? Power Scenario: Grid supply (no turbine initially; future-ready).

? Process Steam: Biomass boiler fired mainly with press fiber + shell (optionally EFB (Empty Fruit Bunches)/wood chips as supplement).

? Quality Targets: CPO (Crude Palm Oil) moisture ≤0.25%, impurities ≤0.25%; stable clarification for good DOBI (Deterioration of Bleachability Index).

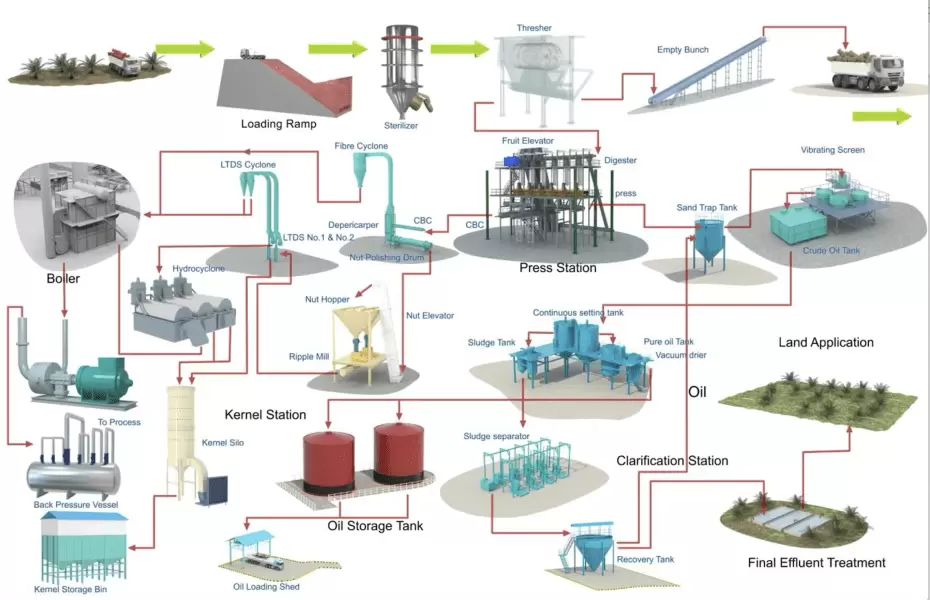

Process & Equipment (Fit-for-Purpose)

? FFB (Fresh Fruit Bunches) Reception & Weighing: Truck tipper, reception hoppers, belt/chain feeders with VFDs (Variable Frequency Drives), weighbridge.

? Sterilization: Horizontal batch sterilizers w/ automatic cycle; steam PRV (Pressure Reducing Valve) station (3–4 barg (bar gauge) process steam), condensate return.

? Threshing: Rotary drum thresher with lifters; EFB (Empty Fruit Bunches) discharge to handling line (mulch/compost/fuel).

? Digestion: Steam-heated digesters (multi-agitator) with temperature/level control.

? Pressing: Twin-screw presses (2 trains for availability) with choke adjustment and dilution injection.

? Primary Oil Screening: Vibratory screens + sand trap tank.

? Clarification & Polishing: Decanter centrifuge (or continuous settling) → disc-stack purifier → vacuum dryer → CPO (Crude Palm Oil) buffer/polished tanks.

? Fiber–Nut Recovery: Depericarper (air), nut conveyors.

? Nut Cracking & Kernel Separation: Ripple mill → hydrocyclone/air table → kernel dryer → kernel silo (PK (Palm Kernel) line-ready).

? Boiler Island (Biomass): 20 barg (bar gauge) class water-tube boiler, economizer, multicyclone, ID/FD fans (Induced Draft/Forced Draft), fuel feed (fiber/shell/EFB), deaerator, BW/condensate tanks (Boiler Water/condensate).

? Water & Effluent: Raw water treatment (filtration/softening), hot-water system, POME treatment (Palm Oil Mill Effluent; anaerobic + polishing), sludge oil recovery.

⚡ Electrical & Control: Main transformer (630 kVA (kilovolt-ampere) typical), MCCs (Motor Control Centers), PLC/SCADA (Programmable Logic Controller/Supervisory Control and Data Acquisition), instrumentation (flow/level/pressure/temp), safety interlocks & E-stops (Emergency Stops).

? HSE & Compliance: HSE (Health, Safety and Environment) fire detection/suppression, guarded drives, platforms/handrails, relief valves, confined-space & pressure-vessel compliance.

Utility Balance (10 TPH – Typical Ranges)

(TPH = tons per hour)

? Throughput & Yield: 10 t/h (tons per hour) FFB → ~2.0–2.3 t/h CPO (20–23% on FFB) + 0.5–0.7 t/h PK after kernel recovery.

? Steam Demand: ~0.7–0.9 t steam/t FFB (metric tons of steam per ton of Fresh Fruit Bunches) → 7–9 t/h average; design boiler 10–12 t/h @ ~20 barg (bar gauge) (PRV (Pressure Reducing Valve) to 3–4 barg (bar gauge) for process), ~15% margin.

⚡ Electrical Load: 12–18 kWh/t FFB (kilowatt-hours per ton) → 120–180 kW average; connected load ~200–250 kW. Transformer ~630 kVA (PF (power factor) & motor starts).

? Water Use: 0.8–1.2 m³/t (cubic meters per ton) → 8–12 m³/h average; peak makeup up to 20 m³/h with cleaning/ETP (Effluent Treatment Plant) needs.

? POME (Palm Oil Mill Effluent) Generation: 0.6–0.9 m³/t → 6–9 m³/h to ETP; design daily ~150–220 m³/d with buffer.

? Biomass Fuel: Primarily press fiber + shell; EFB as supplementary fuel. Plan for occasional wood chips during ramp-up/maintenance.

Plot Plan Concept (High-Level)

? Zones: (1) FFB handling & sterilizers, (2) threshing/digestion/pressing, (3) clarification & tank farm, (4) kernel plant, (5) boiler & utilities, (6) ETP, (7) maintenance/workshop, (8) admin/lab.

?️ Footprint: Process + utilities ~4,000–6,000 m² under roof; full site including roads, laydown, ETP ~1.2–1.5 ha (hectares) (without large anaerobic ponds; add land if lagooning).

? Flow: Gravity-biased layout (sterilizer → thresher → digester → press → clarification) to minimize pumping and improve maintenance access.

Phased CAPEX (USD, Order-of-Magnitude Ranges)

(USD = United States dollars)

(Land excluded; import duties/logistics in/out of Burundi vary—ranges reflect that uncertainty.)

? Baseline (lean/manual stations, settling + purifier): $4.8–6.2M.

? Enhanced (decanter + purifier, robust SCADA (Supervisory Control and Data Acquisition), covered anaerobic digester): $6.8–8.9M.

? Cost Buckets (indicative):

?️ Civil & Buildings: $0.9–1.3M

⚙️ Process & Kernel Equipment (FOB (Free On Board)): $2.8–3.6M

? Boiler & Utilities (FOB (Free On Board)): $0.9–1.4M

? Freight/Insurance/Import (est. 15–20% CIF (Cost, Insurance and Freight) to site): $0.6–0.9M

⚡ Electrical & Automation: $0.5–0.8M

? ETP (Effluent Treatment Plant; anaerobic + polishing): $0.5–0.9M

? Erection/Commissioning/Training: $0.6–0.9M

? Engineering/PM (Project Management)/Contingency (~10%): $0.6–0.8MOPEX Snapshot (Excluding FFB Cost)

? Power (grid): 12–18 kWh/t × tariff → ~$2.0–3.5 per t FFB (tariff-dependent).

? Water & Chemicals: $0.5–1.2 per t FFB.

?️ Maintenance & Spares: 2–3% of TIC/yr (Total Installed Cost per year) (~$120–220k/yr (thousand per year) at mid-range CAPEX).

? Labor: 35–55 headcount across shifts (operations, lab, maintenance, ETP, logistics, admin) → $4–6 per t FFB (assumption band).

? Biomass Fuel: Net low external cost (fiber/shell internal); budget EFB prep/wood-chip supplement.

? All-in (excl. fruit): ~$10–16 per t FFB typical band.

Recommended Spare Parts Package

? Critical 0–6 Months (on site): press worms/cage bars, press gearbox seals, digester bearings/seals, screen decks, purifier/decanter wear parts, pump mechanical seals, valve kits, mission-critical transmitters, VFD (Variable Frequency Drive) spares.

⚙️ 12–24 Months (recommended): full press worm/cage set, ripple-mill liners/beaters, conveyor chains/sprockets, boiler grate/burner spares, instrumentation spares (DP cells (Differential Pressure transmitters), RTDs (Resistance Temperature Detectors)), MCC (Motor Control Center) contactors/relays.

⏱️ Lead-Time Strategy: classify A (≤2 weeks), B (3–6 weeks), C (8–16 weeks) and hold A/B on site.

Training Plan (Operator-Centric)

? Week 1–2 (Classroom): process fundamentals, HSE/LOTO (Health, Safety and Environment/Lockout-Tagout), QC (Quality Control) (FFA (Free Fatty Acids)/M&I (Moisture & Impurities)/DOBI (Deterioration of Bleachability Index)), utilities/boiler ops, ETP (Effluent Treatment Plant) basics, SOPs (Standard Operating Procedures) & checklists.

? Week 3–6 (On-the-Job): line walkdowns, start/stop procedures, alarm handling, press torque optimization, decanter/purifier tuning, shift-handovers, lab sampling, sanitation.

? Week 7 (Assessment): written + practical evaluations; certification by area (pressing, clarification, kernel, boiler, ETP).

Commissioning Timeline (From Mechanical Completion)

? Pre-Comm (pre-commissioning; 2 weeks): loop checks, instrument calibration, motor rotation, flushing/cleaning, boiler hydro (hydrostatic test)/purge.

❄️ Cold Commissioning (1–2 weeks): dry runs, interlock tests, conveyors/presses jog, water runs on clarification/ETP, electrical load tests.

? Hot Commissioning (1–2 weeks): steam-on, sterilizer cycle tuning, hot oil/clarification stability, purifier balance, boiler/condensate optimization.

? Performance Test (1 week): yield, throughput, product specs (M&I (Moisture & Impurities)), utility KPIs (Key Performance Indicators); punch-list closure and handover.

? Ramp-Up (2–4 weeks): progressive throughput to 10 TPH (tons per hour), operator coaching, energy/water optimization.

Deliverables You’ll Receive

? Engineering Dossier: PFDs (Process Flow Diagrams), P&IDs (Piping & Instrumentation Diagrams), I/O list (Input/Output), data sheets, GA (General Arrangement)/plot plan, utility balance.

? Operating Package: SOPs (Standard Operating Procedures), maintenance plans, critical spares list, QA/QC methods (Quality Assurance/Quality Control), commissioning & SAT protocols (Site Acceptance Test).

♻️ Compliance: pressure-vessel files, material certificates, and ETP (Effluent Treatment Plant) mass-balance ready for local permitting.

- For more information:

? : Contact Us