Product Description

- Product Details & Technical Specifications

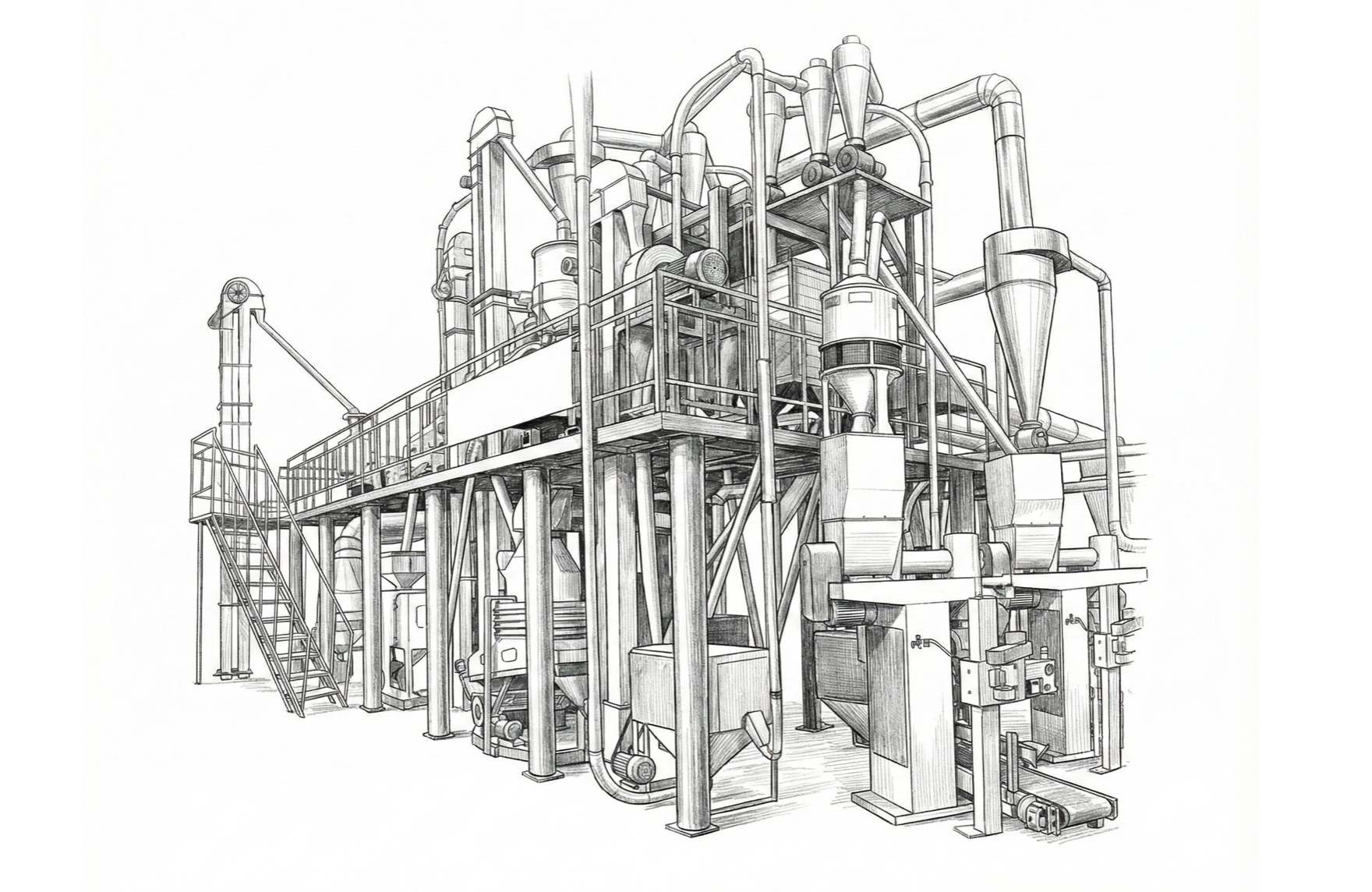

Product Overview

The 100TPD Maize Mill Production Line is a professional-grade, large-scale industrial facility designed to process 100 tons of maize per 24-hour cycle. This turnkey system is engineered for maximum output efficiency, achieving a flour extraction rate of 80% to 95% while producing a high-quality bran byproduct (5% to 20%). The plant utilizes a sophisticated multi-stage process including magnetic separation, vibration cleaning, stone removal, dual-stage peeling, and high-precision milling.

Core Processing Sections

1. Cleaning and Peeling Section

- Magnetic Separation: Dual TCXP20 magnetic separators provide a 99.5% iron removal rate with a magnetic field strength of at least 2000GS.

- Vibration Cleaning: The TQLZ100*150 high-efficiency vibrating screen removes large and small impurities at a capacity of 4 to 5 tons per hour

- De-stoning: A TQSF100 gravity de-stoner accurately removes stones and heavy impurities from the raw grain.

- Dual-Stage Peeling: The system employs both an MNMS30A Emery roller peeling machine (37kw) and an LN300 Iron roller peeling machine (37kw) to ensure complete removal of the outer husk before milling.

2. Flour Milling Section

- Pneumatic Grinding: Five FMFQ60*2 compound pneumatic roller mills provide precision grinding with a combined motor power of over 107kw.

- Sifting & Classification: Five FSFJ83832 double-bin plansifters featuring 13-floor sieve configurations ensure consistent particle size and flour purity.

- Hammer Milling: An SFS60*60 hammer mill (55kw) is integrated to handle specific grinding requirements at a capacity of 2 to 3 tons per hour.

3. Automated Packing and Storage

- Bulk Storage: The system includes two 2.5m x 6m carbon steel silos for flour and feed storage.

- Automatic Packing: A DCS25 flour packing scale and a DCS50 bran packing scale offer 0.1% accuracy and a speed of 100 to 120 bags per hour.

Technical Specifications

Feature

Specification

Production Capacity

100 Tons per 24 hours

Total Power Consumption

356.52 KW

Installation Dimensions

25000 x 9000 x 8500 mm

Flour Extraction Rate

80% to 95%

Logistics Requirements

Three 40HQ Shipping Containers

Lead Time

40 working days after deposit

Installation and Support

- Turnkey Installation: Yubei Machinery provides expert engineers for on-site setup and commissioning.

- Industrial Controls: The system is managed via a centralized main control cabinet and standard national-grade wiring.

- Quality Assurance: All equipment is built from high-grade carbon steel or galvanized sheet depending on application, ensuring long-term industrial durability.

- For more information: