500L/D Turnkey Edible Oil Refinery: Stainless Steel Batch System for Palm & Soybean Oil Processing18960

15.120,00 €

Availability:

In stock

Out of stock

Short Description

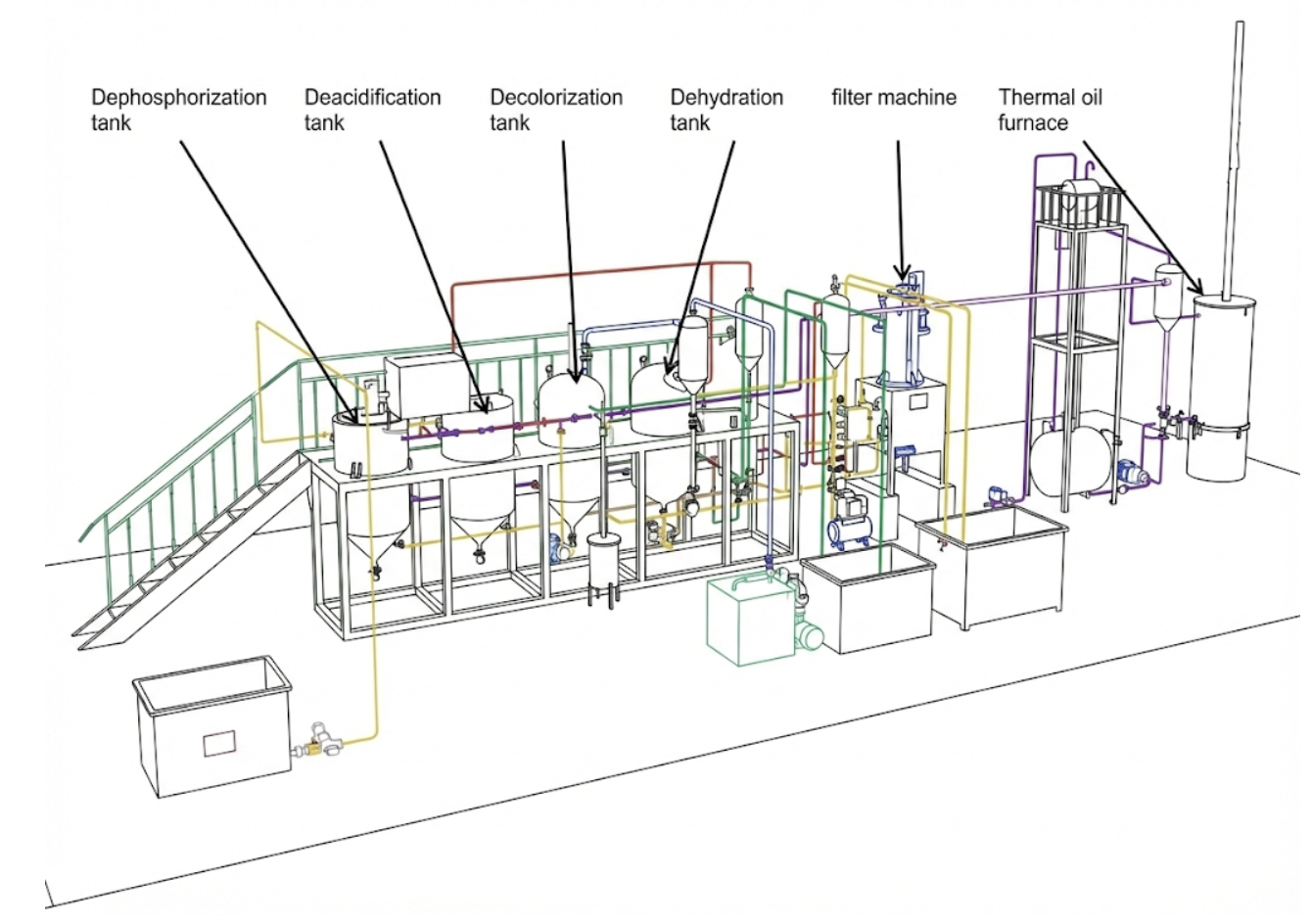

This industrial-grade 500L/D (Liters Per Day) refining system is engineered for small-to-medium scale oil processing enterprises. It provides a complete "crude-to-refined" solution capable of producing Grade 1 RBD (Refined, Bleached, Deodorized) oil. This batch-type refinery is optimized for processing crude palm oil, soybean oil, peanut oil, and other vegetable lipids.

Sector

Product Description

- Product Details & Technical Specifications

Key Process Capabilities The system utilizes a 4-stage physical and chemical refining process to ensure high-quality output compliant with international standards:

- Degumming & Deacidification: Features dedicated hydration and neutralization tanks to remove phospholipids and Free Fatty Acids (FFA) via alkali refining and phosphoric acid treatment.

- Decolorization (Bleaching): Equipped with a vacuum bleaching system utilizing clay adsorption to remove pigments (red color) and trace metals. The process operates under vacuum at 115°C to ensure efficiency.

- Deodorization: High-temperature vacuum distillation (240°C–260°C) removes volatile odorous substances and residual FFA, ensuring a neutral taste and extended shelf life.

- Filtration: Integrated Plate and Frame Filter Press and Safety Filters remove waste clay and solid impurities, ensuring crystal-clear final oil.

Technical Specifications & Materials

- Capacity: 500 Liters/Day (Batch operation).

- Construction Material: Critical contact vessels (Refining, Decolorizing, Deacidification tanks) are constructed from Stainless Steel (S201) for hygiene and durability, while structural components utilize Q235 Carbon Steel.

- Heating System: Includes a Thermal Oil Furnace and a dedicated Steam Producer (Model ZFQ18) for precise temperature control during deodorization.

- Vacuum System: High-performance water ring vacuum pump (Model ZQK2.2) maintaining a working vacuum of 2–267 Pa, essential for preventing oxidation during processing.

- Filtration System: Model BT-500 Safety Filter with 150x150mm plates and internal SS304 components for fine filtration.

Operational Efficiency

- Energy Efficiency: Engineered for low power consumption, targeting less than 10 kW·h per ton of oil processed.

- Consumables: Optimized for low auxiliary consumption (Clay <3%, Phosphoric acid <0.2%).

- Compact Footprint: The complete layout is approximately 6.5m x 5m, making it suitable for facilities with limited space.

- For more information: