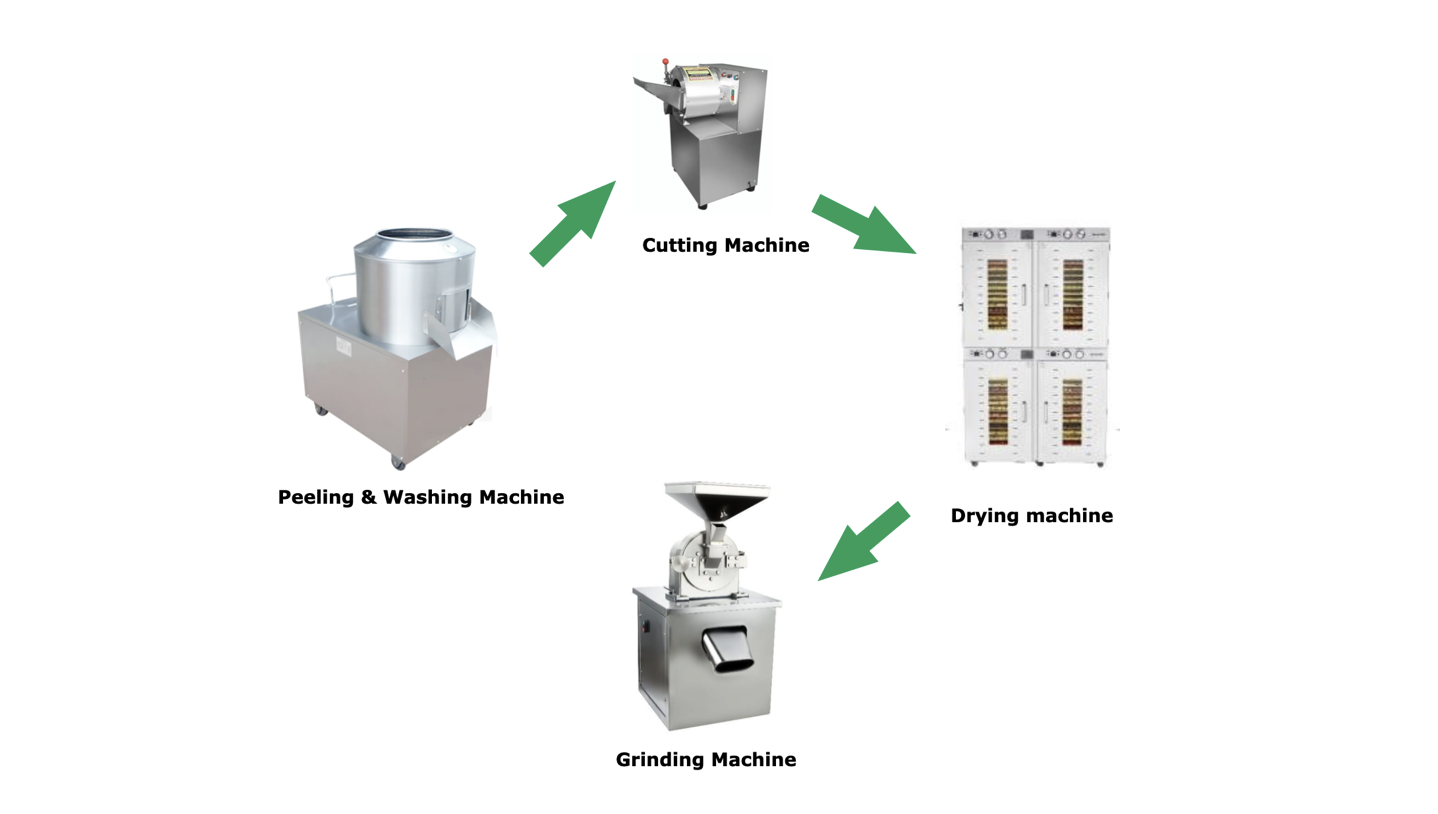

Maximize yield and quality with this complete, automated 100 kg/h Ginger Powder Production Line, engineered for food, spice, and nutraceutical manufacturers. The system integrates four core machines—peeling & washing, precision cutting, controlled drying, and fine grinding—into a seamless, scalable workflow. Built for reliability, hygiene, and consistent output, it transforms raw ginger roots into premium, food-grade powder ready for packaging or further formulation.

Product Description

- Detailed Product Description

As a trusted solution for agro-industrial processors, this Complete Ginger Powder Production Line delivers a continuous throughput of 100 kg of finished powder per hour, optimized for operational efficiency, minimal waste, and compliance with international food safety standards. Each component is selected and calibrated to ensure balanced capacity, energy efficiency, and ease of maintenance—ideal for SMEs and large-scale producers entering or expanding in the functional food, spice, or herbal supplement markets.

1. Automatic Ginger Peeling & Washing Machine – Model MSQ-350

- Throughput: 150–200 kg/h (exceeds line requirement for buffer capacity)

- Power Supply: 1.5 kW, 220V, 50 Hz

- Machine Dimensions: 565 × 415 × 840 mm

- Net Weight: 55 kg | Packed Weight: 75 kg

- Packing: Export-standard wooden crate

- Packed Dimensions: 700 × 530 × 1040 mm | Volume: 0.38 m³

- Key Features:

- Dual-action mechanical peeling with water-assisted cleaning

- Minimizes raw material loss (<5%) while ensuring thorough surface decontamination

- Compact footprint, ideal for small to mid-sized processing facilities

2. Multi-Function Root Vegetable Cutter – Model HQC-611

- Cutting Capacity: 500–800 kg/h (high surplus ensures no bottleneck)

- Motor Power: 0.75 kW, 220V / 50 Hz, single-phase

- Dimensions: 750 × 480 × 890 mm

- Weight: 70 kg

Cutting Versatility:

- Slicing: 2–20 mm thickness (interchangeable blades)

- Shredding: 2–10 mm width

- Dicing: Fixed sizes of 8, 10, 12, 15, or 20 mm

- Application Benefit: Uniform ginger cuts ensure even drying and consistent particle size after grinding—critical for powder solubility and appearance.

3. Industrial Batch Tray Dryer – Model DBJ-88A

- Drying Chamber Capacity: 425 liters

- Tray Configuration: 88 stainless steel mesh trays (396 × 396 mm each)

- Tray Spacing: 30 mm (1.4") for optimal airflow

- Temperature Control: Adjustable 40–90°C (104–194°F)

- Heating Power: 7.4 kW, 220V / 50 Hz

- Dimensions (Unpacked): 870 × 565 × 1550 mm

- Packed Weight: 156 kg | Packed Volume: 1.129 m³

- Key Advantages:

- Gentle hot-air convection preserves ginger’s volatile oils and pungency

- Moisture content reduced to <8–10%, ideal for stable powder storage

- Batch drying allows flexibility for small lots or quality sampling

4. Fine Impact Grinding Mill – Model WN-200

- Grinding Capacity: 30–120 kg/h (adjustable to match 100 kg/h target)

- Particle Fineness: 10–200 mesh (customizable via screen inserts)

- Motor Power: 2.2 kW

- Voltage Options: 220V (single-phase) or 380V (three-phase)

- Spindle Speed: 4,200 RPM

- Noise Level: <85 dB (meets OSHA industrial standards)

- Dimensions: 500 × 550 × 900 mm | Weight: 130 kg

- Performance Highlights:

- High-speed impact grinding ensures smooth, lump-free powder

- Suitable for direct use in teas, capsules, seasonings, or instant beverages

- Easy-clean design with quick-access grinding chamber

System Integration & Operational Benefits:

✅ Balanced Throughput: Upstream units (peeling, cutting, drying) operate above 100 kg/h capacity to prevent bottlenecks and ensure stable grinding output.

✅ Hygienic Design: All food-contact surfaces are made of 304 stainless steel (standard); optional full SS316 upgrade available.

✅ Plug-and-Play Setup: Pre-tested and shipped with wiring diagrams, operation manuals, and remote commissioning support.

✅ Scalable & Adaptable: Same line can process turmeric, galangal, garlic, or other fibrous roots with minor adjustments.

✅ Energy Efficient: Total installed power ≈ 11.85 kW—optimized for cost-effective continuous operation.Target Applications:

- Spice & seasoning manufacturers

- Herbal tea and nutraceutical producers

- Export-oriented agro-processors

- Contract powder manufacturers

- Organic food processing facilities

Ready for Global Shipment – FOB or DDP Options Available.

Invest in a future-proof, high-yield ginger powder line that delivers consistency, compliance, and commercial scalability—engineered for today’s competitive agro-food marketplace.

- For more information:

? : Contact Us