Turnkey 100 kg/h Complete Instant Baby Food Powder Processing Line – Fully Integrated, Hygienic, and Automated System for Nutritional Infant & Adult Instant Flours. Includes Mixing, Extrusion, Drying, Milling, and Conveying Units with Dust-Free & Vacuum Feeding Technology.

Product Description

- Detailed Product Description:

Introducing a fully integrated, industrial-grade 100 kg/h instant baby food powder processing line, engineered for manufacturers specializing in high-nutrition, ready-to-mix flours for infants and adults. This turnkey solution combines precision engineering, food-grade hygiene compliance, and energy-efficient automation to deliver consistent product quality, optimal solubility, and minimal nutrient loss.

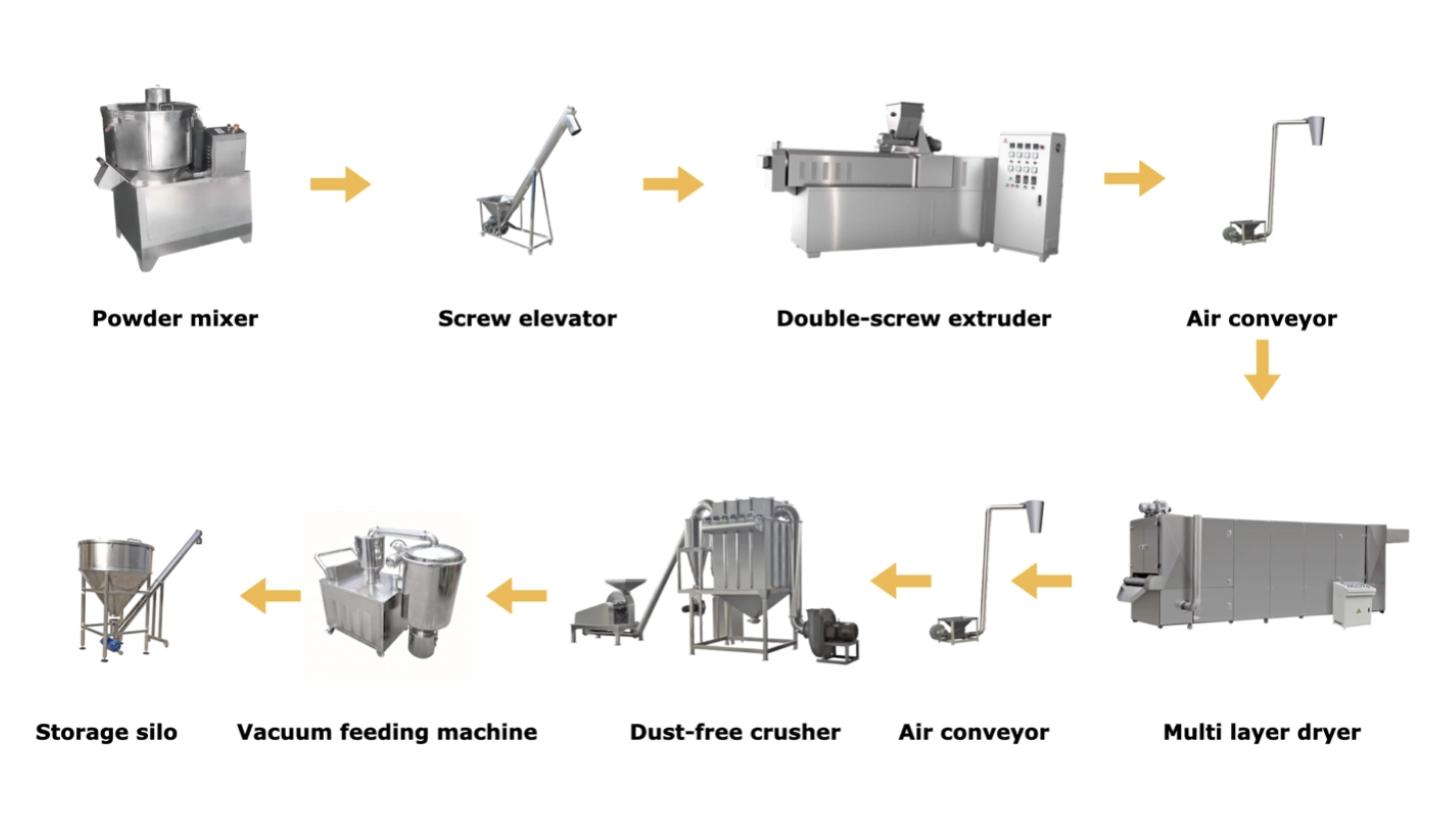

The system is modularly designed for seamless integration into existing facilities and includes the following core components:

1. Powder Mixer – Model BF-Ⅱ (Qty: 1)

- Batch capacity: 50 kg per cycle

- Drive power: 5.5 kW

- Rotating blade diameter: 720 mm | Speed: 205 rpm

- Dimensions: 1200 × 800 × 1160 mm

Ensures homogeneous blending of base flours, vitamins, minerals, and other dry ingredients prior to extrusion.

2. Screw Elevator – Model ZLSJ (Qty: 1)

- Feed screw diameter: φ104 mm

- Drive motor: 0.75 kW | Mixing motor: 1.1 kW

- Dimensions: 3000 × 850 × 2400 mm

Provides gentle, continuous vertical transport of mixed powder to the extruder hopper with integrated pre-mixing action.

3. Twin-Screw Extruder – Model SLG65-C (Qty: 1)

- Processing capacity: 80–120 kg/h

- Screw diameter: 65 mm | Speed range: 0–250 rpm

- Temperature control: 0–399°C (precise zone-wise control)

- Motor power: 22 kW | Center height: 1020 mm

- Dimensions: 2600 × 950 × 2000 mm

Performs high-shear cooking, gelatinization, and expansion under controlled thermal and mechanical conditions—critical for digestibility and instant solubility in infant formulas.

4. Air Conveyors – Model FJ-Ⅰ (Qty: 2)

- Drive power: 0.37 kW each

- Air volume: 900 m³/h | Fan speed: 2000 rpm

- Dimensions: 950 × 420 × 650 mm

Transports extruded pellets and milled powder through enclosed, hygienic pneumatic lines—minimizing contamination and manual handling.

5. Multi-Layer Belt Dryer – Model DKX (Qty: 1)

- Heating power: 26 kW | Main drive: 0.55 kW

- Speed control: 1–1500 rpm (slip-speed regulation)

- Dimensions: 5000 × 1450 × 1650 mm | Weight: 1200 kg

Gently dries expanded extrudates across multiple temperature zones to achieve <5% moisture content while preserving nutritional integrity.

6. Dust-Free Crusher – Model WF-30B (Qty: 1)

- Capacity: 100–200 kg/h

- Particle size: 80–120 mesh (adjustable)

- Motor power: 5.5 kW

- Dimensions: 4500 × 1400 × 3000 mm

Produces fine, uniform instant powder with closed-loop dust collection—ensuring operator safety and product purity.

7. Vacuum Feeding System – Model DKS (Qty: 1)

- Motor power: 3 kW

- Conveying capacity: 1200 kg/h

- Input air pressure: 0.6 MPa

- Dimensions: 700 × 600 × 1000 mm

Enables automatic, contamination-free raw material intake directly from storage silos or big bags.

8. Storage Silo – Model CLT (Qty: 1)

- Dimensions: 1300 × 1300 × 2500 mm

Food-grade stainless steel construction for intermediate or finished product storage with integrated level monitoring (optional).

Key Advantages:

✅ End-to-End Automation – Minimal manual intervention from raw blend to packaged powder

✅ GMP & HACCP Compliant – All contact surfaces in SS304/316; easy-clean design

✅ Energy Efficient – Optimized motor sizing and thermal recovery in drying zone

✅ Scalable Output – Designed for 100 kg/h continuous operation (≈800 kg/shift)

✅ Versatile Formulations – Suitable for rice, maize, soy, oat, or multi-grain blends with added micronutrientsIdeal for startups and established agro-food producers seeking a reliable, compact, and future-ready production line for premium instant nutritional flours.

Ready for immediate delivery. Customization available for voltage (220V/380V/440V), automation level (PLC/HMI), and packaging integration.

- For more information: