Complete Peanut Butter Production Line (100 kg/h)

12.360,00 €

Availability:

In stock

Out of stock

Short Description

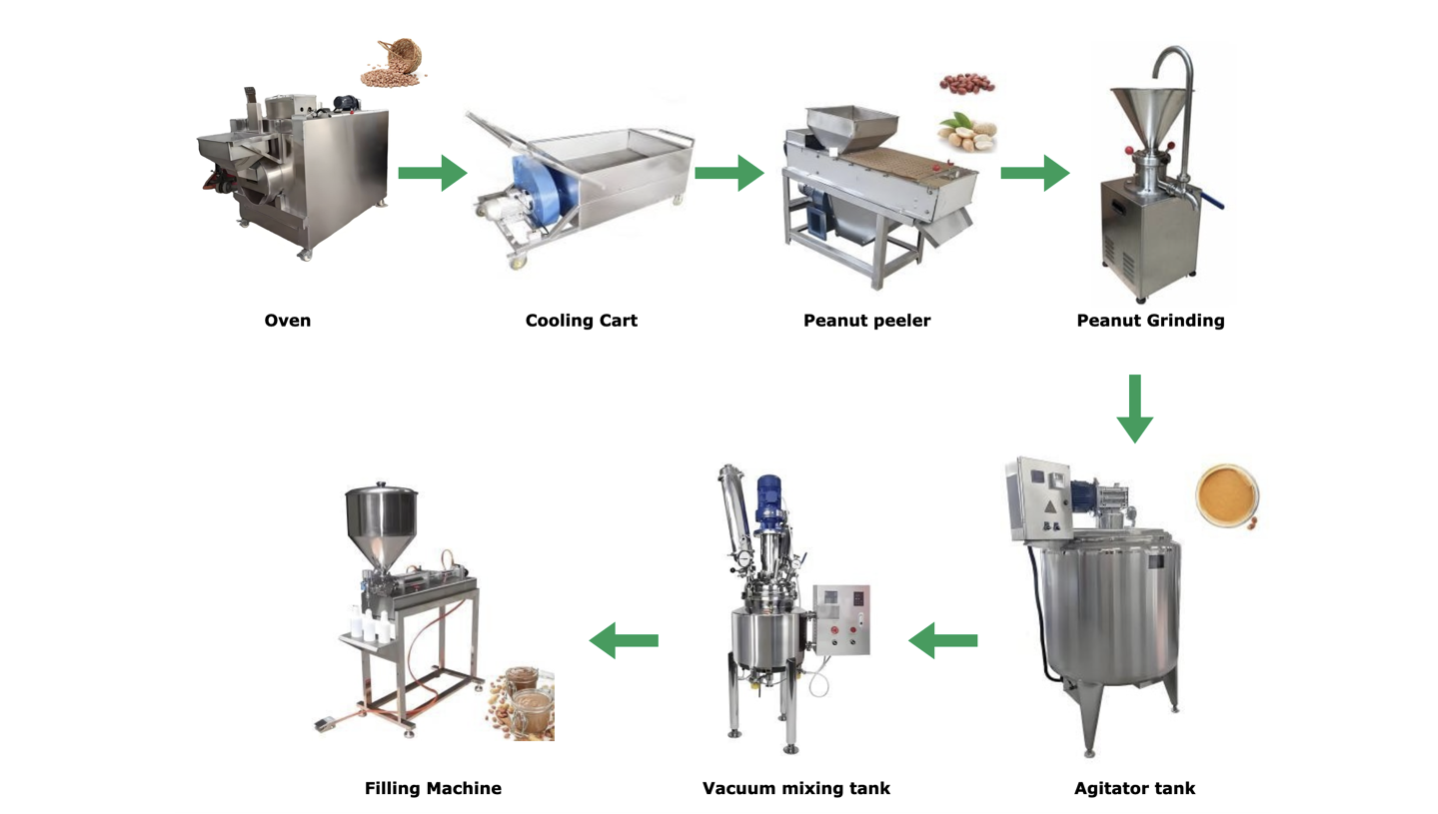

A comprehensive, semi-automatic production line for manufacturing peanut butter or other nut pastes. This turnkey system includes all essential machinery for roasting (100 kg/h), cooling, peeling (250 kg/h), grinding, agitated mixing (50L), vacuum degassing, and pneumatic filling. Key components, including the agitator tank and cooling cart, are constructed from food-grade 304 Stainless Steel.

Sector

TURNKEY FOOD INDUSTRY PROJECT » COMPLETE BUTTER PRODUCTION LINE

Product Description

- Product Details & Included Machinery

This complete line (1 set) includes the following 7 components:

1. Oven (Model: DAH-100)

- Function: Roasting peanuts.

- Capacity: 100 kg/h

- Power: 22 kW

- Voltage: 380V

- Speed: 5-20 rpm

- Insulation: 80mm

2. Cooling Cart (Model: DAT-50)

- Function: Cooling roasted peanuts.

- Material: Stainless Steel 304

- Cooling Volume: 50 kg/h

- Power: 0.37 kW

- Voltage: 380V/220V

- Dimensions: 1.2 * 0.65 *0.65 m

- Weight: 65 kg

3. Peanut Peeler (Model: DAT-250)

- Function: Removing peanut skins.

1 - Peeling Capacity: 250 kg/h

- Power: 0.75 kW

- Voltage: 380V/220V

- Dimensions: 1 *0.5 * 0.9 m

- Weight: 90 kg

4. Peanut Grinding (Model: OLL-60C)

- Function: Grinding peanuts into paste.

2 - Hopper Capacity: 4.5L

- Power: 1.5 kW

- Voltage: 220V

- Dimensions: 0.37 * 0.37 *0.8 m

- Weight: 45 kg

5. Agitator Tank (Model: DAJ-50)

- Function: Mixing peanut butter with other ingredients.

- Material: 304 Stainless Steel

- Volume: 50 kg

- Power: 0.75 kW

- Voltage: 380V/220V

- Stirring Speed: 10-20 rpm

6. Vacuum Mixing Tank (Model: OLL-50)

- Function: Bubble elimination (degassing) from the paste.

- Capacity: 50L

- Includes: Vacuum pump and all piping.

7. Filling Machine (Model: OLL-100)

- Function: Pneumatic filling of the final product.

- Operating Air Pressure: 0.5-0.7 mpa

- Includes: One air compressor.

- Dimensions: 0.7 * 0.25 * 0.8 m

- For more information: