Product Overview

This is a complete, integrated production line for the commercial manufacturing of high-quality potato chips. The system is engineered to handle the entire process, from raw potato input to the final sealed and packaged product. Designed for efficiency, consistency, and food-grade compliance, this line is an ideal solution for small to medium-scale food factories, large commercial kitchens, and food industry entrepreneurs.

Key Features

- End-to-End Solution: Includes all essential machinery for washing, peeling, slicing, frying, de-oiling, flavoring, and sealing.

- System Capacity: The line's effective throughput is governed by the fryer, operating at an estimated 60–70 kg/h of finished product. Upstream components (washer, slicer) feature higher capacities (200–300 kg/h) to ensure a continuous and buffered supply.

- Food-Grade Construction: All primary food-contact machines are manufactured from high-quality stainless steel, ensuring durability, hygiene, and compliance with food safety standards.1

- Consistent Quality: Each component is designed for uniform processing, resulting in consistent chip thickness, fry quality, and even flavor application.

- Operational Voltage: Standardized on 220V / 50Hz (Single Phase for most components).

Product Description

- Complete Semi-Automatic Potato Chip Production Line (60-70 kg/h)

The global demand for snack foods is insatiable, and at the top of the list sits the humble, universally loved potato chip. For entrepreneurs and small-to-medium-sized enterprises (SMEs) looking to enter this lucrative market, the biggest hurdle is often finding an efficient, reliable, and complete production setup.

Look no further. Our Complete Semi-Automatic Potato Chip Production Line is an all-in-one solution designed to take you from raw potatoes to packaged, shelf-ready products with a capacity of 60-70 kg per hour.

This line is engineered for a logical, seamless workflow, ensuring consistency and quality at every stage. Let's walk through the entire process and the machinery that makes it happen.

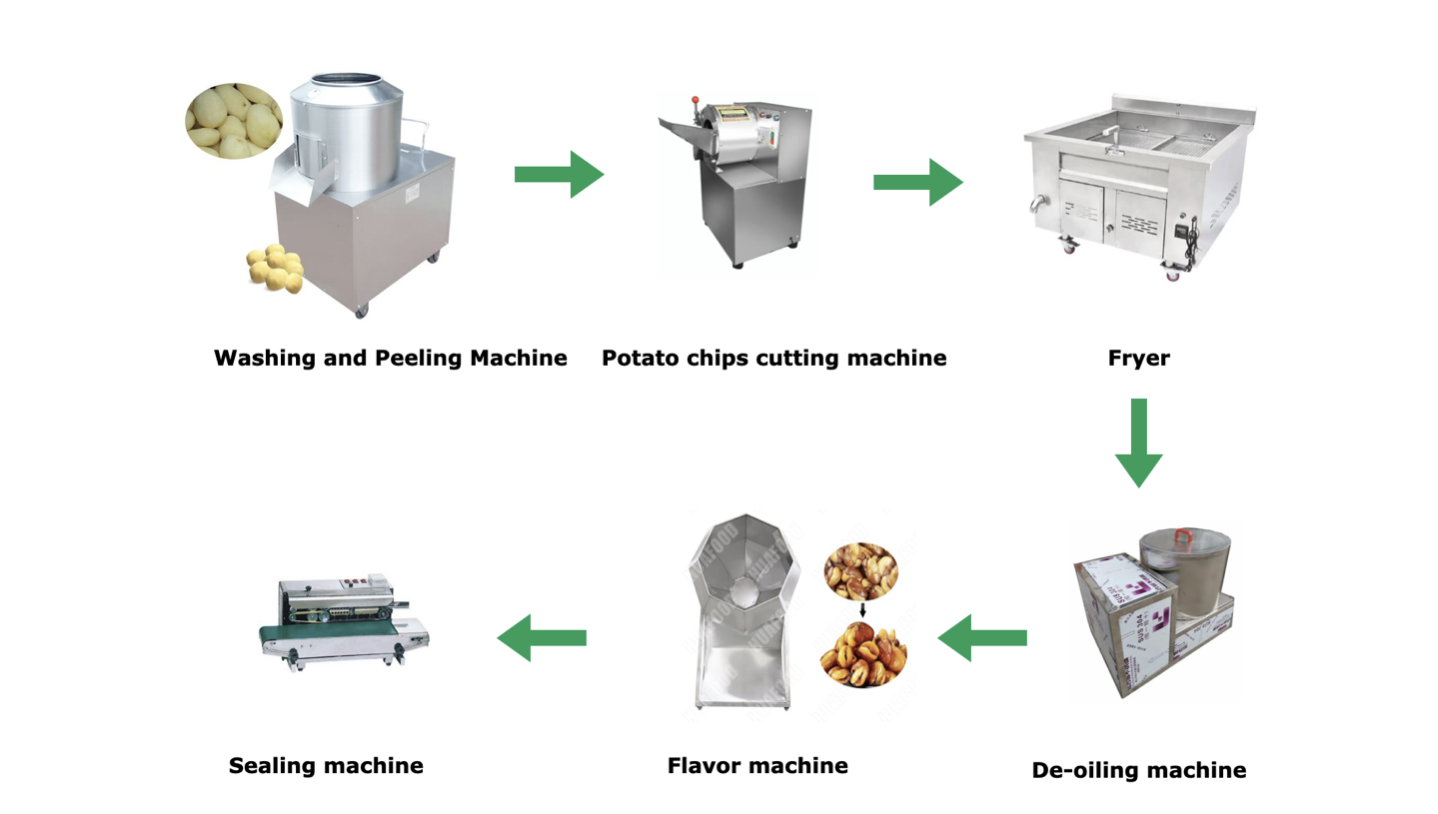

The Overall Production Workflow

The process is a straightforward, linear path that minimizes handling and maximizes efficiency:

Raw Potatoes ----> Washing & Peeling ----> Slicing ----> Frying ----> De-Oiling ----> Flavoring ----> Sealing ----> Final Packaged Product

A Detailed Look at Each Machine Component

This semi-automatic line includes six core machines that handle every step of the transformation.

1. Potato Washing and Peeling Machine

The journey begins with clean, quality ingredients. This machine is the workhorse that prepares your raw potatoes by thoroughly cleaning off soil and debris. It then efficiently removes the skin using a rotating abrasive drum and integrated water jets.

- Model: 350

- Capacity: 200-300 kg/h

- Power: 1.5 kW

- Voltage: 220V

- Machine Weight: 55 kg

2. Potato Chips Cutting Machine

Consistency is key to a perfectly fried chip. Once peeled, the potatoes move to this high-precision cutter. It slices them into uniform thin chips (e.g., 1-2 mm), which is crucial for ensuring that every chip fries evenly to achieve that perfect golden-brown crisp.

- Capacity: 250 kg/h

- Power: 1.5 kW

- Voltage: 220V / 50Hz / Single Phase

- Dimensions (L x W x H): 350 x 450 x 650 mm

- Weight: 40 kg

3. Continuous Fryer

This is the heart of the production line. The raw potato slices are fed into the continuous fryer, which maintains a stable, controlled temperature (approx. 170-180°C). This electric-heated fryer ensures each chip is cooked to crispy perfection. The capacity of this unit (60-70 kg/h) sets the overall throughput for the entire line.

- Heating Method: Electric

- Capacity: 60-70 kg/h (This determines the line's overall throughput)

- Motor Power: 120 W (for conveyance)

- Oil Volume: 150 L

- Weight: 110 kg

4. De-oiling Machine

To achieve a premium, non-greasy product and improve shelf life, the freshly fried chips must be de-oiled. This machine uses centrifugal force to quickly spin off excess surface oil from the hot chips, resulting in a lighter, crispier texture.

- Model: 400

- Power: 1.1 kW

- Voltage: 220V / 50Hz

- Dimensions (L x W x H): 1000 x 500 x 700 mm

- Weight: 80 kg

5. Flavor Machine (Tumbling Drum)

Here's where you add your signature taste. The de-oiled chips are transferred to this rotating tumbling drum. As the drum rotates, it gently tumbles the chips while evenly applying your powdered seasonings, ensuring a consistent and delicious coating on every single chip.

- Model: HBT-700

- Capacity: 280 kg/h

- Power: 0.75 kW

- Dimensions (L x W x H): 900 x 700 x 1300 mm

- Weight: 110 kg

6. Continuous Bag Sealing Machine

The final step in production is to preserve that freshness. This continuous sealer provides a secure, hermetic heat-seal on your pre-filled bags. It protects your final product from moisture and contamination, ensuring your customers get the high-quality, crispy chips they expect.

- Model: FR-880

- Sealing Speed: 0-12 m/minute (Adjustable)

- Sealing Width: 6-12 mm

- Power: 750 W

- Voltage: 220V / 50Hz

- Weight: Approx. 32 kg

Step 7: Final Packaging and Distribution

After sealing, your individual bags are complete. They are now ready for the final workflow step: manual or automated case packing into cartons for bulk storage, transport, and distribution to your eager customers.

Why Choose This Production Line?

This 60-70 kg/h semi-automatic line is the ideal solution for businesses aiming for a significant market presence without the massive capital investment of a fully automated system.

- Complete Solution: It's an end-to-end system from raw vegetable to finished good.

- Ideal Capacity: Perfect for small-to-medium scale producers, local brands, and market testers.

- Cost-Effective: The semi-automatic nature balances machine efficiency with lower initial cost and maintenance.

- Quality & Consistency: Each machine is designed to work in sync, producing a uniform, high-quality, and marketable product batch after batch.

Ready to start your journey in the snack food industry? This complete production line is your first step.

- For more information: