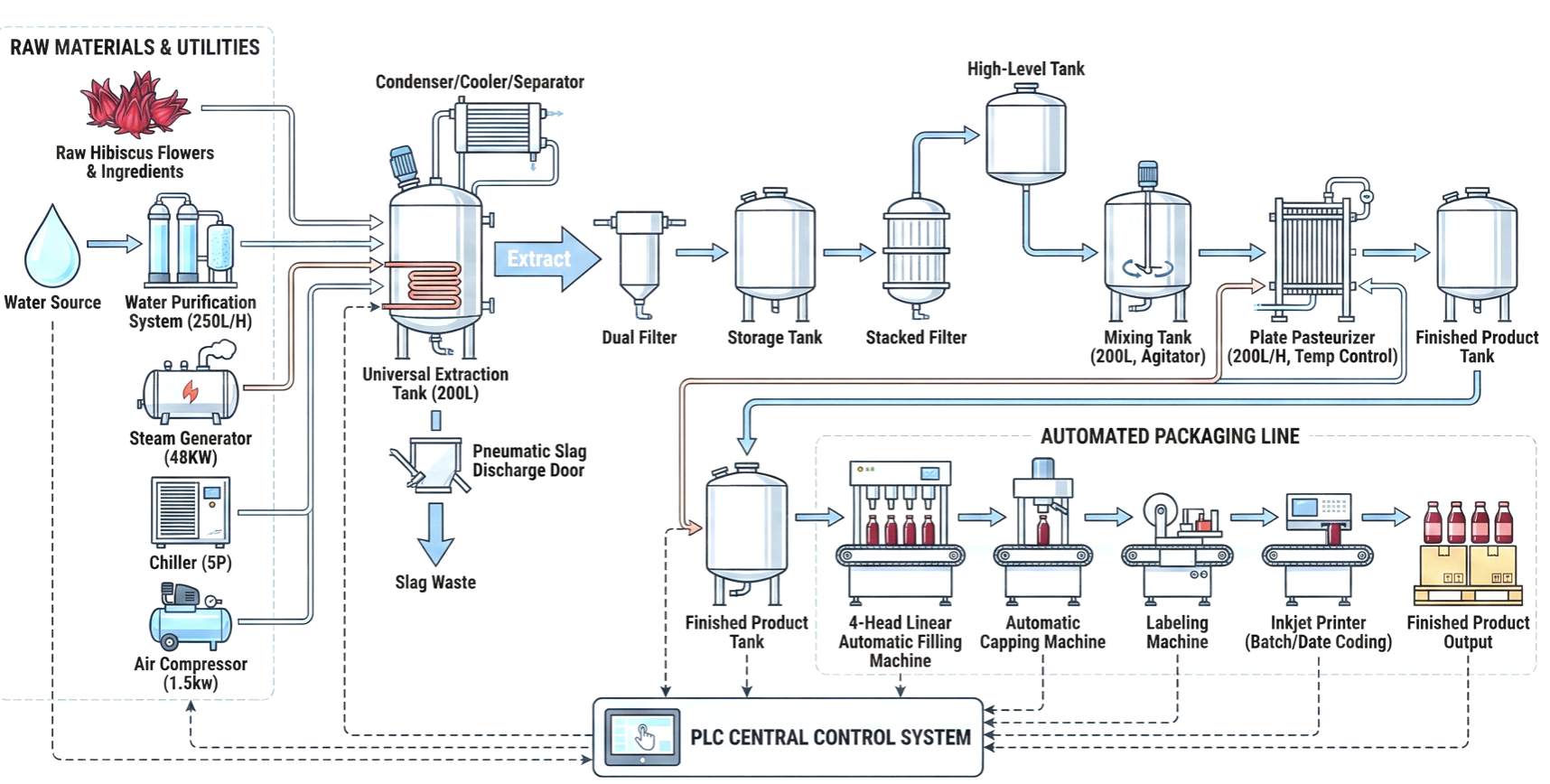

Scale your agri-food business immediately with this comprehensive, industrial-grade production line designed for high-efficiency hibiscus syrup manufacturing. This turnkey solution covers the entire processing cycle—from raw material extraction to final packaging. Featuring a 200L Universal Extraction Tank with a pneumatic quick-open slag door for safety and ease of use, the system ensures premium product quality with GMP-compliant SUS304 stainless steel construction.

The line is fully automated, boasting a 200L/H Plate Pasteurizer, a 4-head Linear Automatic Filling Machine (up to 1200 pcs/h), and precision capping and labeling units. Supported by essential utilities like a 48kw Electric Steam Generator, Chiller, and Reverse Osmosis Water Purification, this system is engineered for reliability, hygiene, and high output. Perfect for beverage manufacturers looking to streamline operations and guarantee consistent, high-quality production.

Product Description

- Product Details & Technical Specifications

This offer includes a complete, professional-grade manufacturing line specifically configured for the extraction, filtration, pasteurization, and packaging of hibiscus syrup and similar liquid beverage products. All primary contact parts are fabricated from high-grade SUS304 stainless steel, ensuring durability and strict adherence to food safety (GMP) standards.

1. Extraction & Filtration System

- Universal Extraction Tank (200L): Vertical cone design with a pneumatic quick-open slag discharge door. Features a 2.5m² condenser, 0.3m² cooler, and oil-water separator. The inner surface is mirror-polished (Ra 0.45) for hygiene.

- Filtration: Includes a Dual Filter (DN200) for initial clarification and a Stacked Filter (DN300) with a 0.22-3um filtration area for fine particle removal, ensuring a crystal-clear final product.

- Storage & Transfer: Equipped with two 200L storage tanks (pre- and post-filtration), a high-level tank, and hygienic centrifugal pumps (1T/H) for seamless fluid transfer.

2. Processing & Pasteurization

- Mixing Tank (200L): A triple-layer insulated tank with a powerful 4KW, 3-phase motor agitator (14000r/min) for uniform blending of ingredients.

- Plate Pasteurizer: Continuous sterilization capability with a flow rate of 200L/H, ensuring product safety and shelf stability.

3. Automated Packaging Line

- Filling: 4-Head Linear Automatic Filling Machine capable of handling 100-2000ml volumes at a speed of 1200 pieces/hour.

- Capping: RY-PLHS-200 Automatic Capping Machine (2000 pcs/h) suitable for bottles ranging from 500-1500ml.

- Labeling & Coding: High-speed Labeling Machine (30-60 pcs/min) for cylindrical containers, paired with a versatile Inkjet Printer (LF2000) for batch coding and expiration dating.

- Conveyor System: A 10-meter conveyor with a dedicated 0.75kw power head connects the packaging stations for continuous workflow.

4. Essential Utilities & Controls

- Water Purification: 250L/H system to ensure water used in production is pure and contaminant-free.

- Steam Generation: 48KW Electric Steam Generator producing 64kg/h of steam for heating and extraction processes.

- Cooling: 5P Chiller (5.9kw input) providing chilled water (5ºC - 25ºC) for rapid cooling and temperature control.

- Air Supply: 1.5kw Air Compressor delivering 1 m3/min$ to power pneumatic components.

- Central Control: A centralized PLC Control System with touch screen operation for easy monitoring and management of the entire line.

- For more information: