This comprehensive Tiger Nut Milk Production Line is a professional, industrial-grade solution designed for the efficient processing of plant-based milks, including nut, almond, peanut, and soybean milk. Engineered by a manufacturer with over 20 years of experience and ISO 9001 certification, this integrated system offers a "one-stop" solution that covers the entire production cycle from grinding to bottling.

Product Description

- Product Details & Technical Specifications

Key Specifications

- Total Capacity: 100-200 KG/H

- Primary Material: Food-grade Stainless Steel (304 and 420 Martensitic)

- Power Source: Electric (Components range from 0.02 KW to 7.5 KW)

- Warranty: 3 Years (free air-shipped replacements for quality-related defects on parts like motors, rotors, and stators)

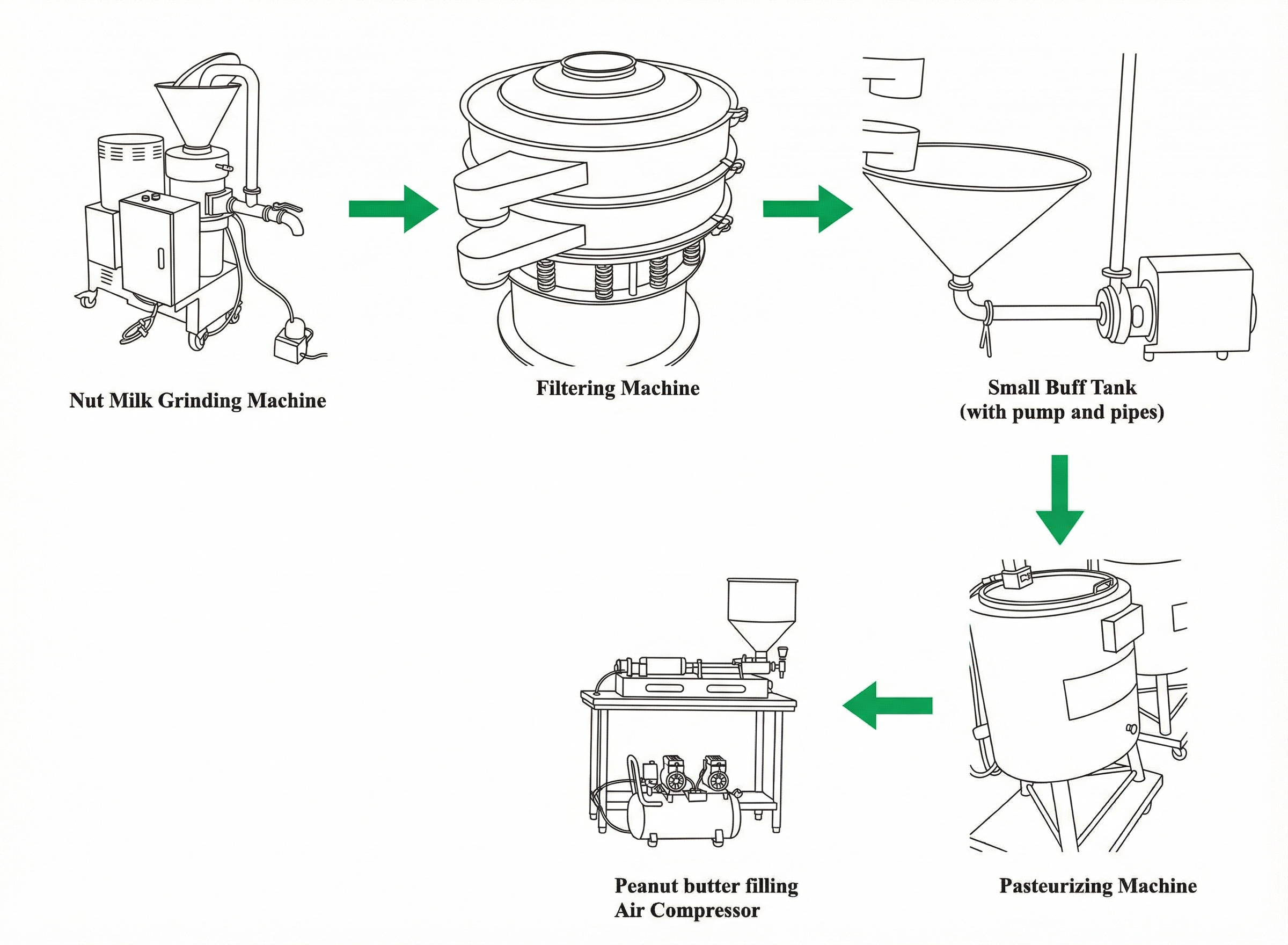

Component Breakdown

1. Tiger Nut Milk Grinding Machine

The core of the system, this unit grinds raw nuts with water into a fine milk emulsion.

- Capacity: 100-200 KG/H

- Motor Power: 7.5 KW}

- Dimensions: Approx. 640 x 940 x 1090 MM

- Construction:

- Feeder/Discharger: 304 Stainless Steel

- Stator & Rotor: 420 Martensitic Stainless Steel (2Cr13) for high durability

- Cover: Food-grade Stainless Steel

- Features: Includes control cabinet, removable wheels for mobility, water pump, pipes, and a circulation system.

2. Filtering Machine

Ensures a smooth product texture by removing coarse particulates.

- Function: Tiger Nut milk filtration

- Motor Power: 0.75 KW

- Dimensions: Height 800 MM, Diameter 800 MM

- Outlets: 2

- Material: Stainless Steel

3. Small Buff Tank (Storage)

Acts as an intermediary station between filtration and pasteurization.

- Volume: 30 Liters

- Dimensions: Diameter 420 MM

- Material: All food-contact parts are 304 Stainless Steel

- System: Equipped with a pump and pipes to automatically transfer milk to the pasteurizer.

4. Pasteurizing Machine

Critical for food safety and extending shelf life.

- Tank Volume: 50Liters

- Total Power: 6.25 KW

- Dimensions: Approx. 650 x 650 x 1350 MM

- Performance:

- Temperature Range: 75-95ºC$

- Time Range: 0-30 minutes

- Material: 304 Stainless Steel

5. Bottle Filling Machine

A versatile filling unit suitable for viscous liquids like Tiger nut milk or peanut butter.

- Filling Capacity: 30-40 Bottles/Minute

- Filling Volume: Adjustable 10-1000 ML

- Dimensions: 920 x 340 x 330 MM

- Filling Heads: 1

- Material: Food-contact parts are 304 Stainless Steel; cover is 201 Stainless Steel.

- Air Pressure Requirement: 4-6 KG

6. Air Compressor

Powers the pneumatic filling machine.

- Motor: 3 KW

- Tank Capacity: 30 Liters

- Air Pressure: 0.8 Mpa

- Displacement: 200 L/Minute

- Dimensions: 550 x 240 x 550 MM

- For more information: