Industrial Grade Hibiscus Syrup Plant: 100L/H Vacuum Evaporator & 200L Mixing System - Complete Juice Processing Line

19.308,00 €

Availability:

In stock

Out of stock

Short Description

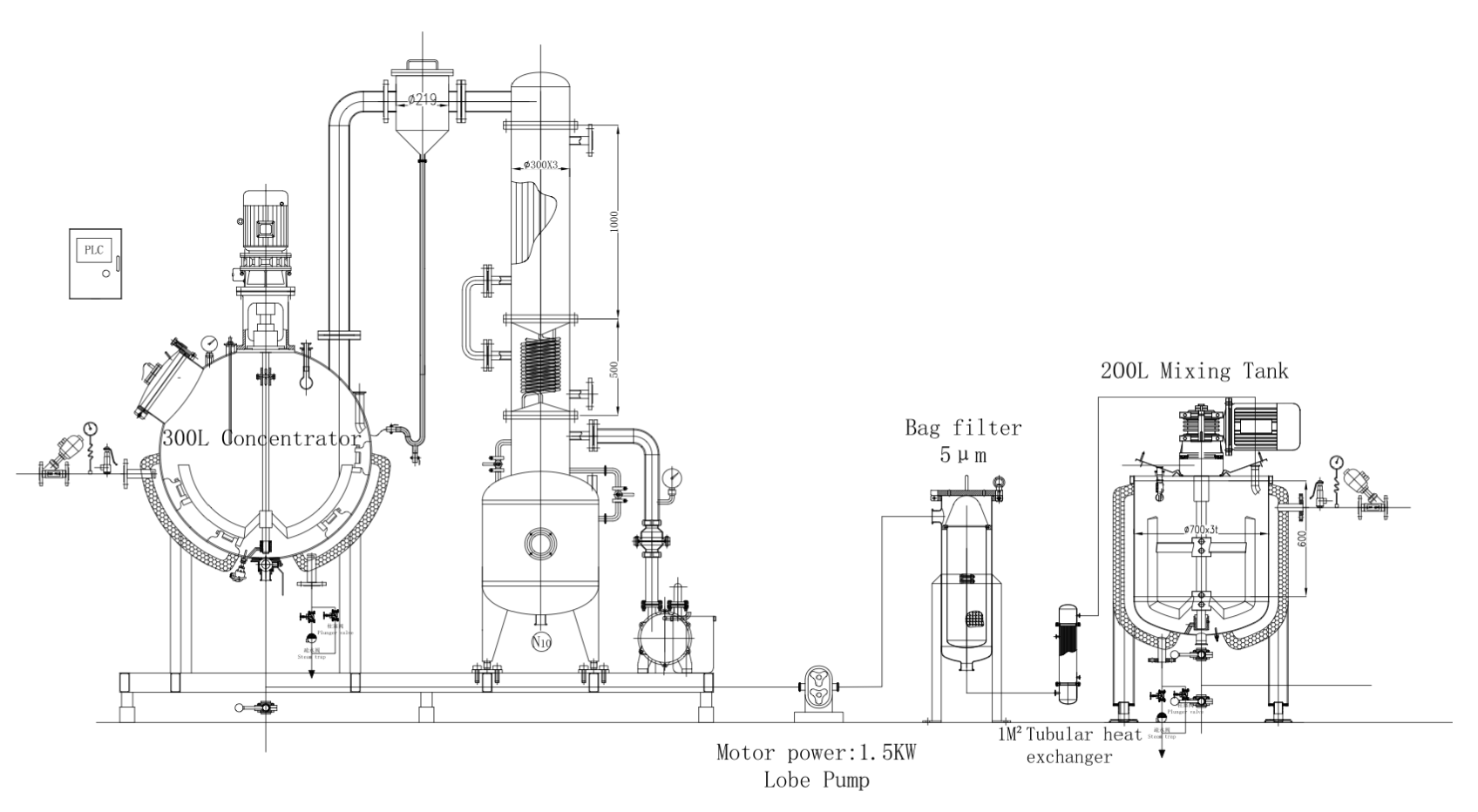

We are offering a comprehensive, high-performance production line specifically engineered for the concentration and mixing of food-grade liquids. This system utilizes low-temperature vacuum evaporation to preserve the flavor and nutrients of heat-sensitive products (such as Hibiscus syrup), combined with robust mixing and filtration capabilities.

Sector

TURNKEY FOOD INDUSTRY PROJECT » COMPLETE SYRUP PROCESSING LINE

Product Description

- Product Details & Technical Specifications

1. High-Performance Vacuum Evaporator System (300L) Designed for efficient concentration at lower temperatures to maintain product integrity.

- Capacity: 300L Volume with 100L/H Evaporation Capacity.

- Material: Full SUS304 Stainless Steel construction.

- Operating Temperature: 60- 80ºC (Preserves heat-sensitive ingredients).

- Agitation: Scraped wall agitator (2.2KW/23RPM) ensures even heat transfer and prevents sticking.

- Heating: Jacketed steam heating (1.2M2 area) with pneumatic angle seat valve temperature control.

- Includes: 4.0KW Vacuum pump, gas-liquid separator, control box, and stainless steel support frame.

2. Sanitary Jacketed Mixing Tank (200L) A robust vessel for blending and temperature maintenance.

- Volume: 200 Liters.

- Construction: Triple-layer insulation (Inner 4mm, Jacket 2mm, Insulation 1.5mm) .

- Finish: Inside mirror polish for hygiene; outside matte 2B plate.

- Agitator: Anchor-type agitator (1.1KW, 43RPM) for thorough mixing.

- Features: Half-open lid and pneumatic angle seat valve for steam heating control.

3. Advanced Automation & Control

- PLC Control Box: Features a premium Siemens brand system for reliable, centralized operation of the production line.

4. Fluid Transfer & Filtration System

- Sanitary Lobe Pump (LNP-8R): 1.5KW motor, variable speed (200-500RPM), and flow rate of 850-2160L/H. Features three rotors and double mechanical seals for hygienic transfer .

- Bag Filter Housing: SUS304 construction with mirror polish (Ra<0.4um). Supports high flow (theoretical 30T/H) and includes 4# filter bags for precision filtration (5\mu m) .

5. Auxiliary Equipment

- Tubular Heat Exchanger: 1m2 surface area for efficient thermal exchange.

- Standard Voltage: 3 Phase / 380V / 50Hz.

Why Choose This Line?

- Certified Quality: Manufactured by an ISO9001:2000 and CE accredited factory.

- Durability: All contact parts are made of sanitary SUS304 stainless steel.

- Support: Comes with a 12-month warranty and long-term technical assistance.

- For more information: