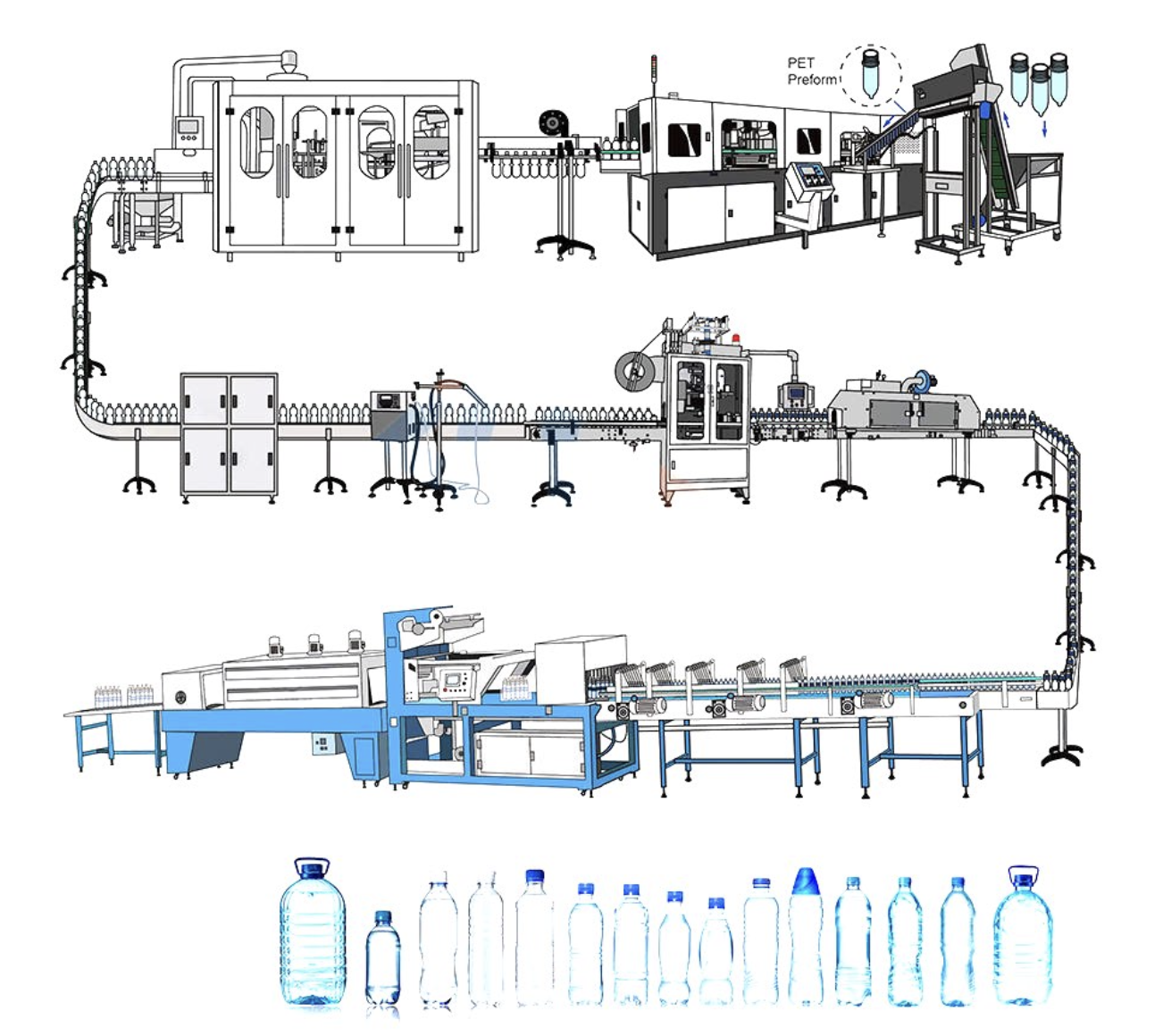

This industrial-grade production line is designed for the complete processing, bottling, and packaging of mineral or spring water. The system integrates water treatment, bottle blowing (semi-automatic), gravity filling, and final packaging into a cohesive workflow. It is optimized for 500ml PET round bottles with a rated output capacity of 2,000 to 3,000 bottles per hour (BPH) for the filling section.

Product Description

- Product Details & Technical Specifications

1. Part 1: Water Treatment System (Capacity: 3,000L/H)

A comprehensive Ultrafiltration (UF) water treatment system designed to purify raw water while retaining essential minerals.

- Filtration Stages: Includes a raw water pump feeding into a multi-media filtration unit (silica sand/manganese sand) and an activated carbon filter to remove sediment, odors, and organic impurities. A precision PP (Polypropylene) micron sediment filter ensures fine particle removal.

- Purification Core: Features a 3,000L/H UF (Ultrafiltration) device with SUS304 pipeline connections.

- Sterilization: Equipped with an Ultraviolet (UV) Water Sterilizer (Model UV-3T) for pathogen elimination without chemical additives.

- Storage: Includes a 3,000-liter Stainless Steel (SUS304) Production Water Storage Tank with a wall thickness of 3mm.

2. Part 2: Bottle Fabrication System

A semi-automatic blow molding station designed to produce PET bottles on-site.

- Molder Specs: Semi-automatic Blow Molder with a capacity of 800–1,000 BPH.

- Versatility: Capable of producing bottles ranging from 200ml to 2.0L.

- Auxiliary Equipment:

- Preform Heater: 10KW unit for softening PET preforms.

- High-Pressure Air System: Includes a 3.0bar/1.2m³ air compressor, a 30bar/0.6m³ air tank, an air filter (2.0/30), and an air cold dryer to ensure clean, dry air for molding.

- Mold: Includes one set of blowing molds specifically for 500ml bottles.

3. Part 3: Filling and Packaging Line (Tribloc System)

The core processing unit featuring an automated washing, filling, and capping monoblock.

- Bottle Transport:

- Air Conveyor: 5-meter SUS304 air conveyor with dust-proof covers and an anti-dust air purifier to feed empty bottles into the filler.

- Filled Bottle Conveyor: 50-meter flat conveyor system with a buffer time of 3-4 minutes.

- Tribloc Unit (Model 8-8-3): A rotary system combining Rinsing (8 heads), Filling (8 heads), and Capping (3 heads).

- Capacity: 2,000–3,000 BPH (based on 500ml bottles).

- Method: Gravity filling type operating at normal atmospheric temperature.

- Compatibility: Designed for 500ml round PET bottles (13–17g weight) with standard HDPE screw caps.

- Accessories: Includes a caps elevator and a SUS304 cap hopper.

- Post-Fill Processing:

- Bottle Drier: 1.5-meter drying zone (7.5KW) to remove moisture from bottle exteriors prior to coding.

- Coding: Ink Date Coder for batch/date printing.

- Labeling: Semi-automatic shrink sleeve labeling machine, complete with a shrink label tunnel and steam generator for PVC labels.

- Final Packaging: Full-automatic Film Wrapper & Shrinker capable of 10 packages per minute (supporting 2x3, 3x4, 4x5, and 4x6 bottle configurations).

4. General Specifications

- Material: Primary construction using SUS304 Stainless Steel for hygiene and durability.

- Labor Requirement: Designed to be operated by a team of 8–9 workers.

- Operating Environment: Max temperature 50°C.

- For more information: