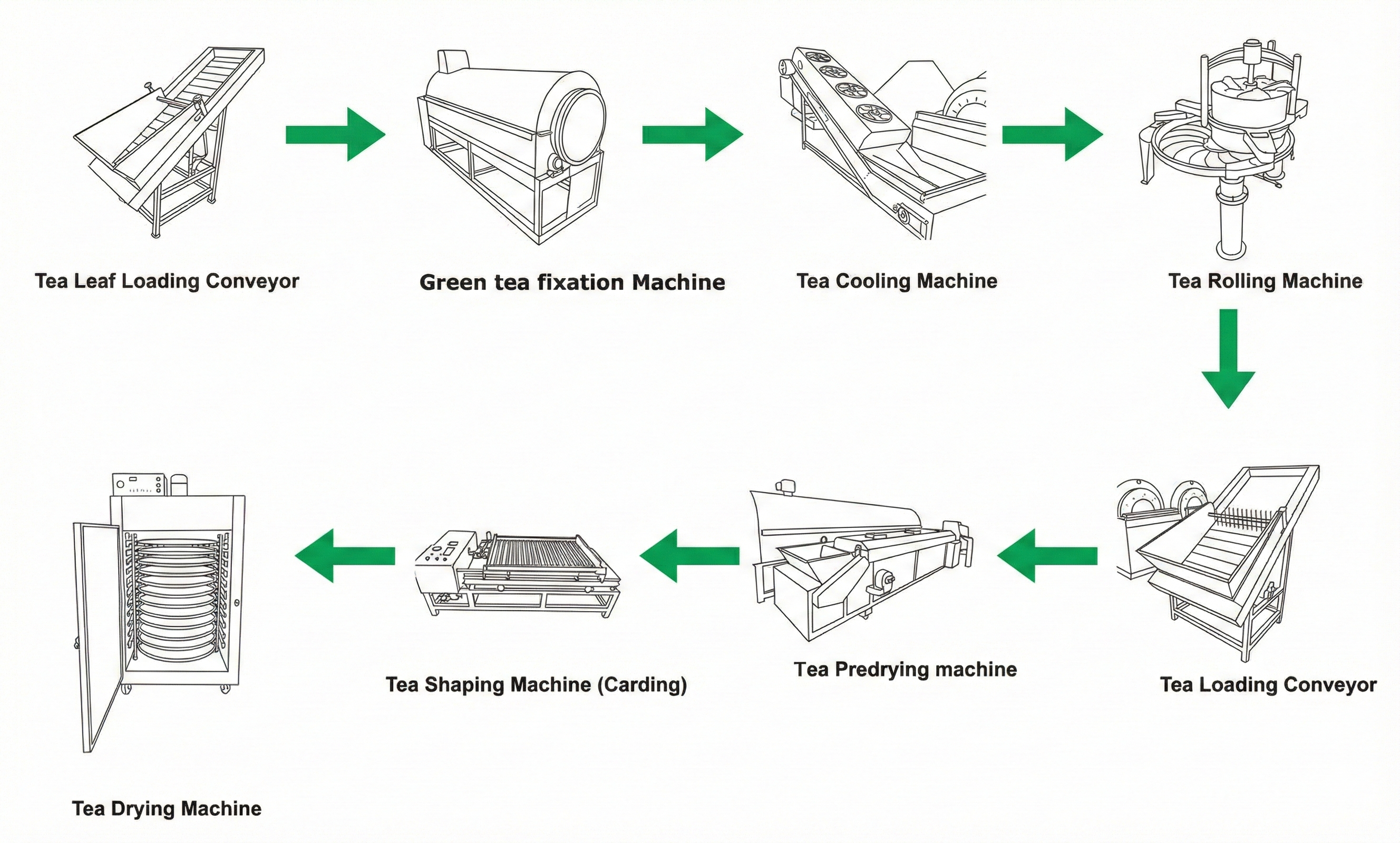

This comprehensive production line utilizes a sequential thermal and mechanical process to transform raw tea leaves into market-ready green tea. The workflow integrates advanced fixation, cooling, rolling, and multi-stage drying to ensure optimal flavor preservation and leaf aesthetics. Constructed with 304 stainless steel on all food-contact surfaces, this line meets rigorous food safety standards while providing the durability required for industrial agri-food processing.

Product Description

- Product Details & Technical Specifications

Component Technical Specifications

1. Raw Material Handling (Loading Conveyors)

The line utilizes two specialized conveyor stages to maintain a consistent flow:

- Initial Loading (FS-40-3): Features an adjustable speed motor (0.12 KW) to regulate input flow.

- Intermediate Loading (FS-65-3): A larger unit (1.66 x 0.75 x 1.7 m designed to move semi-processed leaves between stages

- Construction: Carbon steel frames with 304 stainless steel contact parts.

2. Green Tea Fixation Machine (Model 6CST-70)

This critical unit deactivates oxidative enzymes to maintain the green color and fresh aroma.

- Capacity: 300 kg/h per set.

- Thermal Control: High-powered 65 KW electric heating reaching temperatures of 150–200ºC.

- Efficiency: Rapid fixation time between 0.5 to 2 minutes.

3. Tea Cooling Machine (Model CM-3500)

Prevents over-processing by rapidly reducing leaf temperature post-fixation.

- Cooling System: Equipped with 4 sets of 0.37 KW fans.

- Design: A 3.5-meter long belt 0.5 m width) ensures uniform air exposure.

4. Tea Rolling Machine (Model 6CR-55)

Facilitates cell wall breakdown to enhance flavor extraction during brewing.

- Performance: Processes 100–120 kg/h with a 2.2 KW motor.

- Build: Heavy-duty construction with a unit weight of 380 kg.

5. Tea Pre-drying & Shaping (Models TD-5 & 6CL60-16)

- Pre-drying (TD-5): A 5-meter long automated electric dryer with 36 KW heating power to reduce initial moisture.

- Shaping/Carding (6CL60-16): Uses 9 KW of heating power to shape the tea into its final aesthetic form over an 8-minute cycle.

6. Final Tea Drying Machine (Model YB-16)

The final stage ensures shelf-stability and moisture uniformity.

- Configuration: 16-tray cabinet design for precise batch drying.

- Capacity: 50 kg/h with specialized 0.75 KW fans for moisture evacuation.

- For more information: