Turnkey Industrial Instant Coffee Plant (250kg/h Output): Complete Spray Drying & Aroma Recovery Line - Complete Instant Coffee Powder Processing Plant

2.362.536,00 €

Availability:

In stock

Out of stock

Short Description

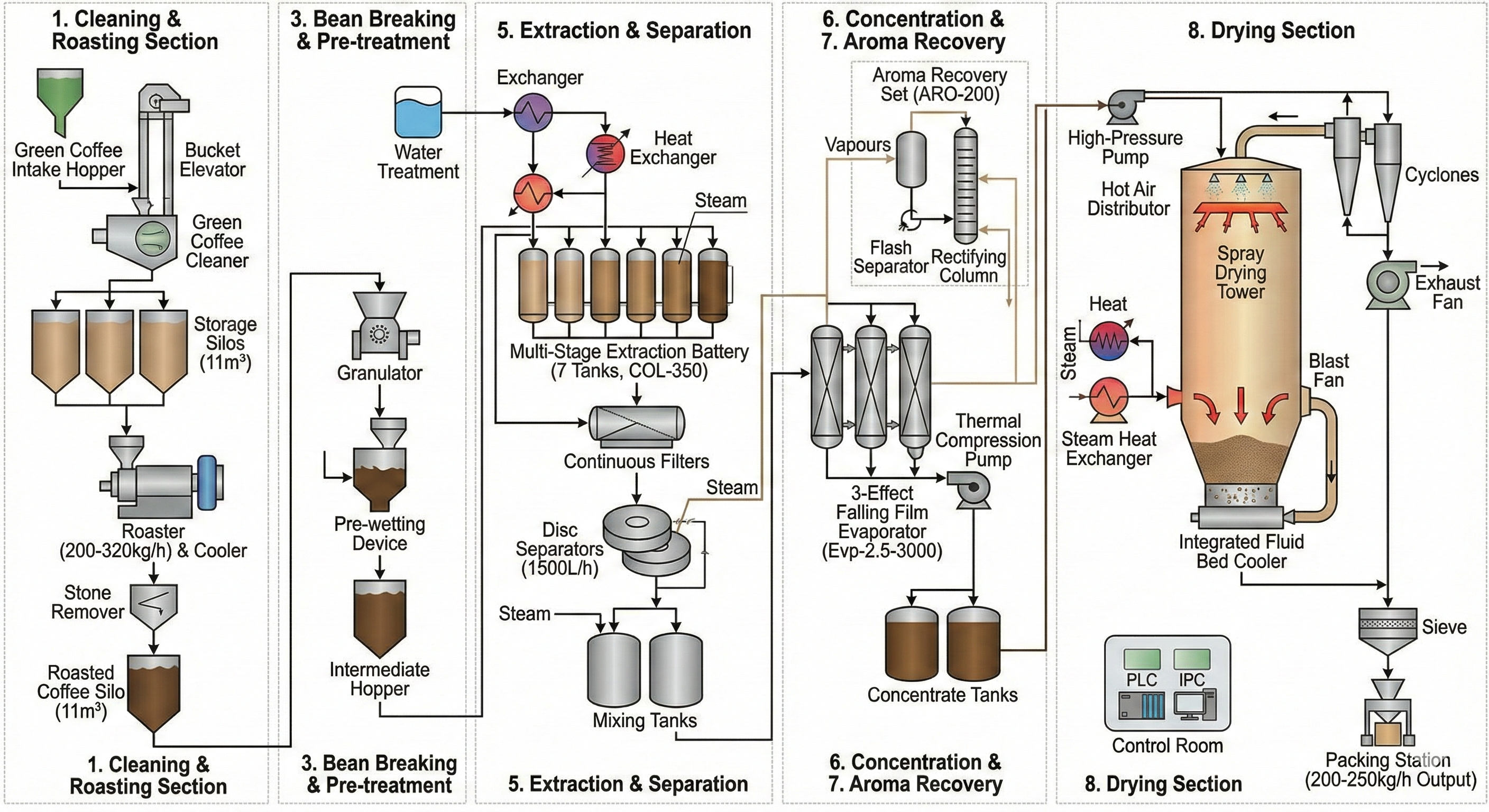

This offer includes the complete scope of supply for a modern instant coffee processing plant. The system is designed for a seamless workflow from raw material handling to the final spray-dried product, utilizing advanced thermal and mechanical separation technologies.

Sector

TURNKEY FOOD INDUSTRY PROJECT » COMPLETE INSTANT COFFEE POWDER PROCESSING PLANT

Product Description

- Product Details & Technical Specifications

Key Technical Sections & Specifications:

1. Green Coffee Handling & Roasting

- Cleaning Section: Includes bucket hoisters, pneumatic conveying (400kg/h), magnetic separation, and storage silos (11m3) to prepare green beans.

- Roasting Section: Equipped with a gas combustion roaster (200-320kg/h capacity) featuring a cooling device, destoner, and chaff collector.

- Bean Preparation: Includes a bean breaking section with a granulator (300kg/h) and pre-wetting devices to optimize extraction efficiency.

2. Extraction & Water Treatment

- Water System: Comprehensive treatment unit including Reverse Osmosis (RO) and Ion Exchange (5m3/h) with high-pressure feeding pumps (20bar).

- Extraction Battery: Seven (7) COL-350 extraction tanks with high-pressure capabilities, equipped with heat exchangers and continuous filters. This section utilizes a multi-stage process to maximize soluble solid recovery.

- Clarification: Features two disc separators (1500L/h) to remove insoluble solids and clarify the extract prior to concentration.

3. Concentration & Aroma Recovery

- Evaporation: A 3-effect Falling Film Evaporator (Evp-2.5-3000) capable of evaporating $3500kg/h$ of water. Includes thermal compression pumps and condensers to concentrate the coffee extract efficiently.

- Aroma Recovery Unit (ARO-200): A specialized system designed to capture and preserve volatile coffee aromatics. It includes a flash separator, rectifying column, and condenser array to reintegrate premium aroma into the concentrate.

4. Spray Drying System

- Drying Tower: Industrial spray drying tower featuring high-pressure nozzle atomization, steam heat exchangers, and a vibration fluid bed for secondary drying/cooling.

- Air Handling: Includes dehumidifiers, blast fans, and extensive filtration (60-mesh inlet filters) to ensure sanitary drying air conditions.

- Product Collection: Equipped with cyclones, rotary valves, and a fines return system to minimize product loss.

5. Automation & Control Architecture

- PLC System: Centralized control utilizing Siemens S7-300 and S7-200 PLCs for reliable logic processing.

- HMI/SCADA: Industrial PC (IPC) integration for real-time monitoring and data logging.

- Instrumentation: High-precision sensors including Endress+Hauser (E+H) vortex flowmeters, pressure transmitters, and temperature sensors.

- Drives: Variable Frequency Drives (Inverters) provided by Schneider/Telemecanique for energy-efficient motor control.

Additional Information

- Materials: Contact parts and critical vessels are constructed from stainless steel (SS304).

- Power Supply: Standard 380V/50Hz/3Phase (customizable).

- Installation Support: Supplier provides supervision for installation and commissioning, including operator training.

- For more information: