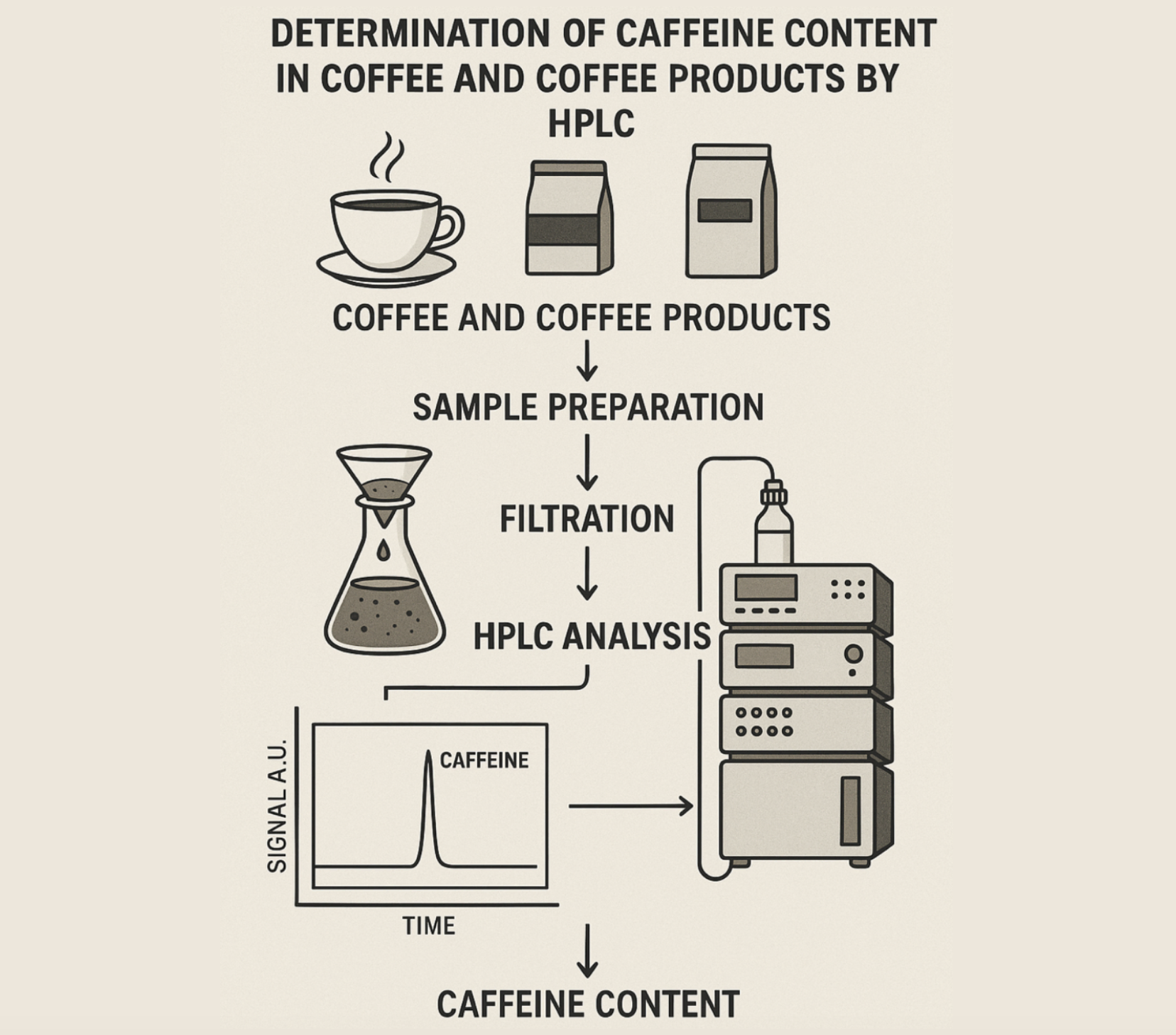

Laboratory Standard Operating Procedure (SOP): Determination of Caffeine Content in Coffee and Coffee Products by HPLC

- Laboratory Standard Operating Procedure (SOP): Determination of Caffeine Content in Coffee and Coffee Products by HPLC

Scope

This SOP describes the reference method for determining the caffeine content in green coffee, roasted coffee, soluble coffee (regular and decaffeinated), and mixed instant coffee products using High Performance Liquid Chromatography (HPLC).

1.0 Principle

Caffeine is extracted from the sample with hot water (≥90°C) in the presence of Magnesium Oxide (MgO), which acts as an adsorbent to protect the HPLC column from co-extracted interferents, especially from green coffee. The extract is filtered and injected into an HPLC system. Caffeine is separated on a reversed-phase C18 column using an isocratic methanol-water mobile phase and detected by UV absorption at approximately 272 nm. Quantification is achieved by comparing the peak area (or height) of the sample to that of a certified caffeine standard.

2.0 Health, Safety, and Precautions

- PPE: Wear lab coat, safety glasses, and nitrile gloves throughout the procedure.

- Fume Hood: Dispense all reagents, especially methanol, in a fume cupboard (fume hood).

- Chemical Hazards:

- Methanol (HPLC Grade): Flammable liquid and vapour. Toxic if swallowed, in contact with skin, or if inhaled.

- Magnesium Oxide (MgO): Avoid generating and inhaling dust.

- Waste Disposal: Dispose of all organic solvents and chemical waste according to local regulations for hazardous waste.

3.0 Apparatus and Equipment

- Analytical Balance: Capable of weighing to ± 0.1 mg.

- HPLC System: Equipped with:

- Isocratic or quaternary pump

- UV-Vis Detector (set at 272 nm) or DAD

- Manual or auto-sampler injection system

- Data collection and integration software

- HPLC Column: Reversed-phase C18 column (250 mm × 4.6 mm, 5 µm particle size).

- Membrane Filter Unit: 0.45 µm pore size, for filtering mobile phase and sample extracts.

- Volumetric Flasks: Class A, 1 L and 250 mL.

- Pipettes: Class A, 5 mL and 50 mL.

- Magnetic Stirrer with Heater and mounted water bath.

- Ultrasonic Bath: for degassing mobile phase.

- Grinders:

- Coffee Mill: for roasted coffee beans.

- Cog-wheel or Analytical Grinder (with cooling): for green coffee beans.

- Sieve: 630 µm nominal opening size.

- Syringe: 10 µL or larger for manual injection (if applicable).

- Vials: HPLC vials with caps.

4.0 Reagents

- Use only reagents of recognized analytical grade.

- Use Grade 1 water (ISO 3696 / IS 1070:1992) for all preparations.

- Methanol: HPLC grade.

- Magnesium Oxide (MgO): Heavy, high grade. Note: Critical for column longevity. Check for interfering peaks.

- Caffeine: Pure anhydrous reference standard.

- Mobile Phase: 24% (v/v) Methanol in Water.

- Pipette 240 mL methanol into a 1 L volumetric flask.

- Make up to the mark with water, mix thoroughly.

- Filter and Degas: Filter through 0.45 µm membrane, then degas in ultrasonic bath for 20 min or use online degasser.

- Caffeine Standard Solutions:

- Stock Solution (200 mg/L): Dissolve 0.200 g caffeine in 1 L volumetric flask, fill with water. Stable 1 month at +4°C.

- Working Standard (Regular Coffee ~40 mg/L): Dilute 50 mL stock to 250 mL with water. Prepare fresh daily.

- Working Standard (Decaf Coffee ~4 mg/L): Dilute 5 mL stock to 250 mL with water. Prepare fresh daily.

- (Optional) Prepare a multi-point calibration curve (5, 10, 15, 20, 25 mg/L).

5.0 Sample Preparation

- Green Coffee: Grind until >50% passes 630 µm sieve. Homogenize.

- Roasted Coffee: Mill until >50% passes 630 µm sieve. Homogenize.

- Soluble Coffee: No grinding needed. Homogenize powder.

- Mixed Beverages (e.g. cappuccino powder): Homogenize immediately before extraction.

6.0 Procedure

6.1 Test Portion Weighing

- Roasted & Green Coffee / Mixed Beverages: Weigh ~1.0 g into 250 mL flask.

- Instant Coffee: Weigh ~0.5 g into 250 mL flask.

6.2 Caffeine Extraction

- Add 5.0 g MgO to the flask.

- Add ~200 mL water.

- Heat in boiling water bath until ≥90°C.

- Continue heating 20 minutes, shaking occasionally.

- Cool to room temperature under running water.

- Make up to 250 mL mark with water. Let solids settle.

6.3 Extract Preparation

- Take aliquot of clear supernatant.

- Filter through 0.45 µm filter into HPLC vial. Discard first mL.

6.4 HPLC Analysis

- System Setup: HPLC conditions:

- Mobile Phase: 24% Methanol in Water (isocratic)

- Flow Rate: 1.0 mL/min

- Detection: UV at 272 nm (or 254 nm)

- Injection Volume: 10 µL

- Column Temperature: Ambient

- System Equilibration: Stabilize for 10 min after pressure stabilizes.

- Calibration: Inject caffeine working standard.

- Sample Analysis: Inject filtered sample extract.

- Sequence: Inject standard after every 6 samples.

7.0 Calculation

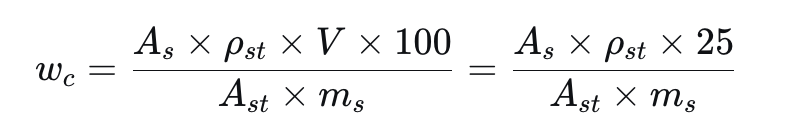

7.1 Caffeine Content (as is basis): Calculate using the formula below.

Where:

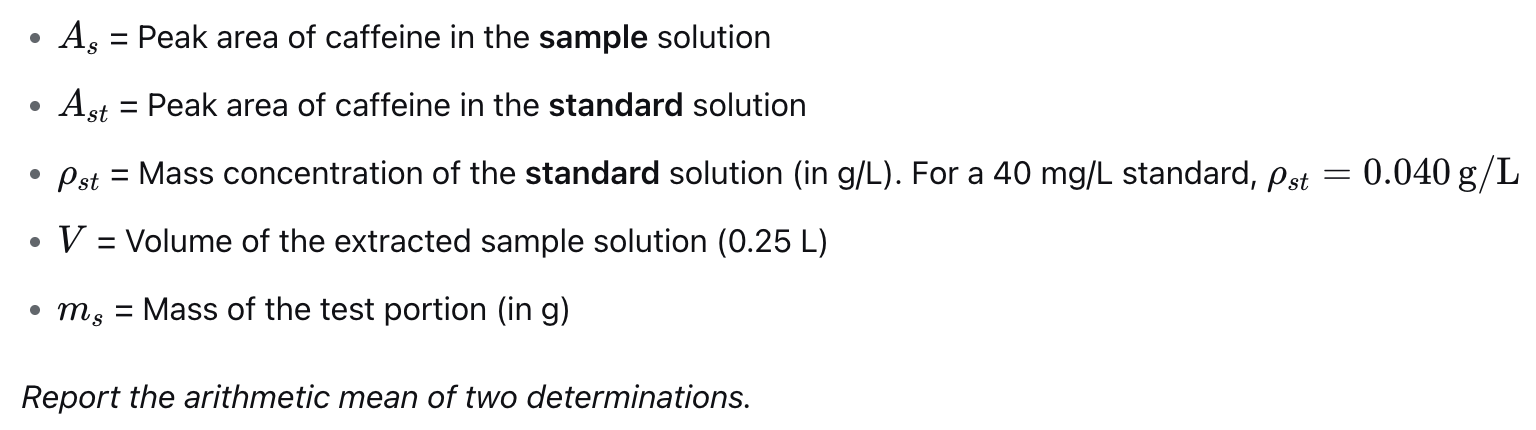

7.2 Caffeine Content (dry basis – optional):

8.0 Quality Control & Precision

- Calibration Verification: Analyze standards regularly.

- Duplicates: Analyze in duplicate. Results must not exceed repeatability limit (r).

- Control Chart: Maintain CRM/control standard chart.

- Precision Values: Refer to precision data (Table 1).

9.0 Reporting

- a) Complete sample identification

- b) Reference to method (IS 16028:2012)

- c) Result as % caffeine by mass (state if dry basis)

- d) Any deviations from procedure

- e) Any unusual observations

- For more information:

? : Contact Us