Complete Soap Production Line (35-50 kg/h Capacity)

8.640,00 €

Availability:

In stock

Out of stock

Short Description

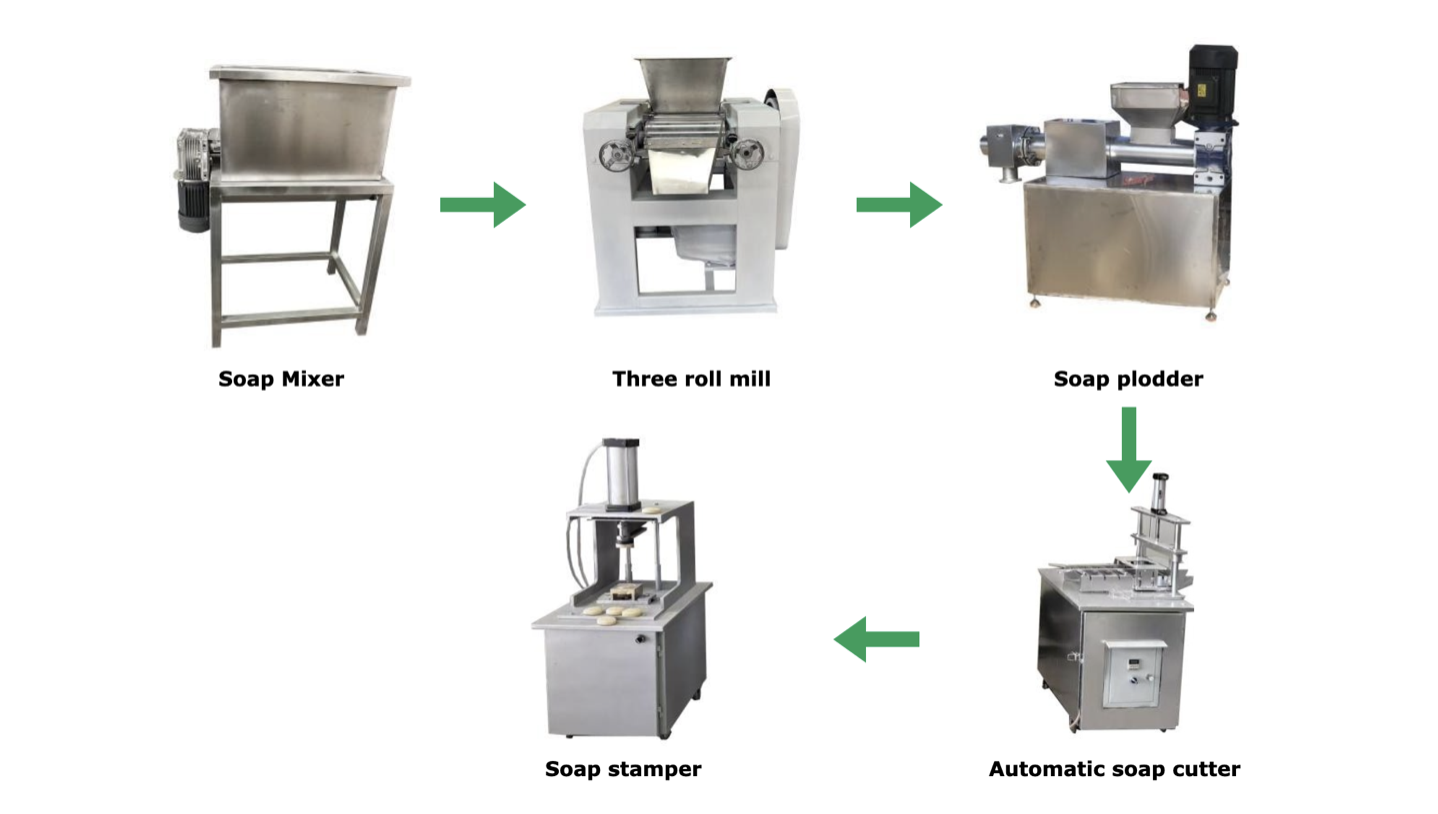

A complete, semi-automatic production line for manufacturing bar soap from soap noodles. This line includes all essential machinery to mix, refine, extrude, stamp, and convey finished soap bars. With a production capacity of 35-50 kg/h, this system is ideal for small to medium-scale manufacturing, pilot plants, or artisan soap makers scaling up operations.

Sector

TURNKEY FOOD INDUSTRY PROJECT » COMPLETE SOAP PRODUCTION LINE

Product Description

- Product Details & Included Machinery

This production line includes the following 5 components:

1. Mixer (1 SET)

- Function: Mixes soap noodles and other ingredients (e.g., fragrance, color).

- Capacity: 25-35 kg/batch

- Motor Power: 4 kW

- Dimensions (LWH): 1200 * 600 * 1000 mm

- Weight: 200 kg

2. Three-Roller Mill (1 SET)

- Function: Grinds and refines the soap mixture from flakes into a smooth, uniform paste.

- Motor Power: 4 kW

- Roller Speed (r/min): Low (13), Middle (35), High (96)

- Dimensions (LWH): 1000 * 900 * 1100 mm

- Weight: 600 kg

3. Double Screw Plodder (Extruder) (1 SET)

- Function: Compacts and extrudes the refined soap paste into a continuous soap bar.

- Capacity: 35-50 kg/h

- Motor Power: 4 kW

- Screw Diameter: 120 mm

- Dimensions (LWH): 1500 * 600 * 1100 mm

- Weight: 350 kg

4. Stamping Machine (1 SET)

- Function: Cuts the continuous soap bar and stamps a logo or design onto the individual bars.

- Capacity: 30-40 pcs/min

- Dimensions (LWH): 400 * 300 * 600 mm

- Weight: 40 kg

5. Conveyor (1 SET)

- Function: Transports finished soap bars (e.g., from the stamping machine to a packaging area).

- Length: 3 meters

- Motor Power: 0.37 kW

- Dimensions (LWH): 3000 * 400 * 800 mm

- Weight: 60 kg

- For more information: