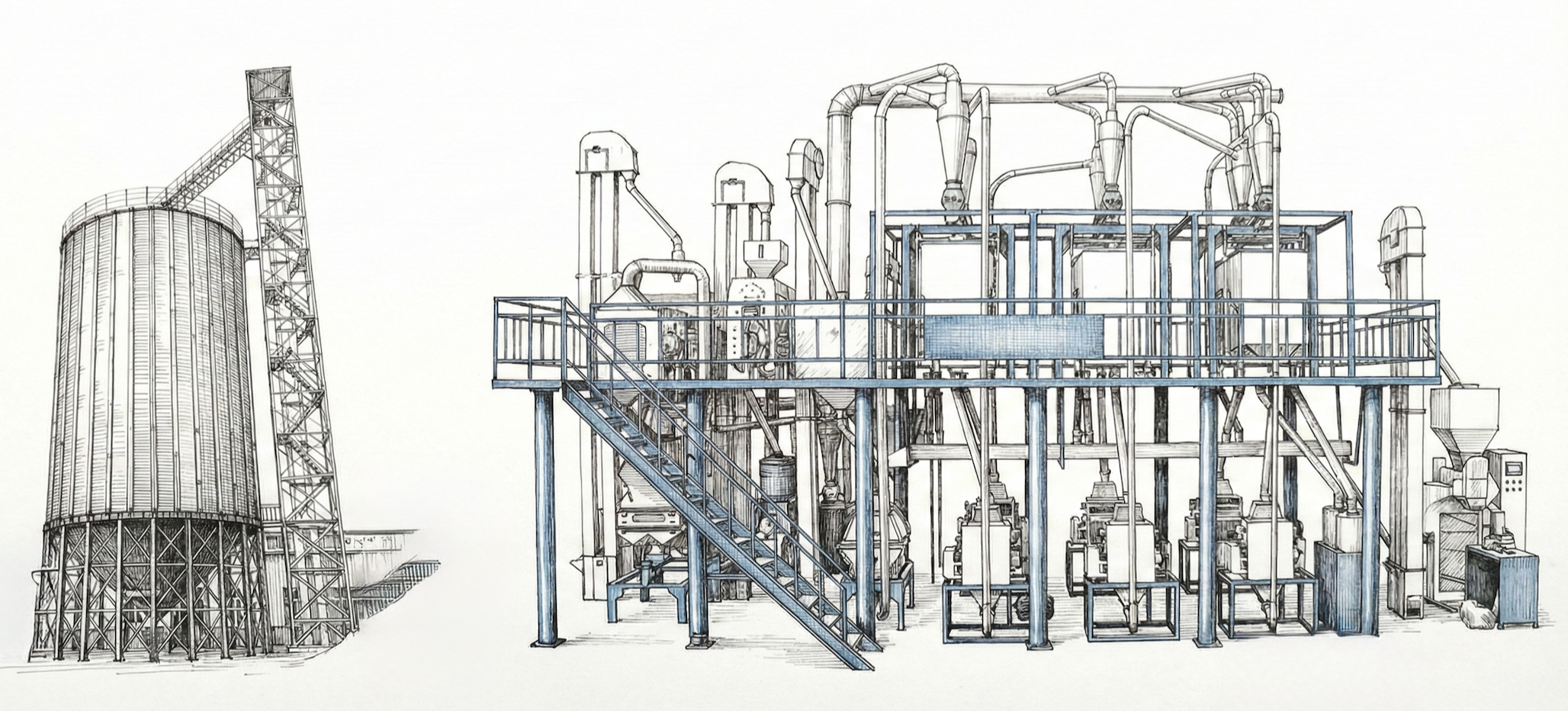

This comprehensive agro-processing facility offers a complete "farm-to-flour" solution, engineered for high-efficiency grain handling, long-term storage, and precision milling. Designed for industrial scalability, this turnkey line integrates a 100-ton continuous drying system, a 200-ton galvanized steel silo with advanced environmental monitoring, and a fully automated 60 TPD (Tons Per Day) maize flour milling plant. The system is built with corrosion-resistant materials and PLC-driven automation to ensure maximum yield, food safety, and operational longevity.

Product Description

- Key Technical Specifications & Sub-Systems

1. High-Efficiency Grain Drying System (100 Tons/Day)

Designed for continuous operation, this tower dryer ensures uniform moisture reduction while preserving grain quality.

- Capacity: 100 Tons daily raw grain processing.

- Structure: Heavy-duty tower (2.4m x 3.4m x 19m) constructed from high-strength 440 galvanized steel sheets (2.5mm thickness) and Grade 8.8 bolt assemblies.

- Thermal System: Features a dual-layer combustion chamber with a 1.2 Million Kcal burner and a 5HL-100 hot wind blower delivering 20320-36000~m3/h airflow.

- Automation: Equipped with real-time monitoring and automatic temperature control for precise drying cycles.

2. Smart Storage Silo (200 Tons)

A state-of-the-art storage solution featuring superior environmental protection and smart monitoring.

- Volume & Dimensions: 275~m3 volume (206-ton capacity), 5.5m diameter, and 15.49m total height.

- Material Technology: Roof plates utilize cold-based Zn-Al-Mg alloy coating (SGC350 grade), offering 5 times the heat and corrosion resistance of standard galvanized steel. Wall panels feature double-sided zinc coating (275g/m2).

- Smart Preservation: Includes a ventilation system (roof axial fans + centrifugal fans), an armored temperature-sensing cable system (measurement range -55ºC to 125ºC), and rotary paddle level detection.

- Sealing: Aerospace-grade sealant paste ensures air-tight storage, extending grain shelf life up to 30 years.

3. 60 TPD Maize Flour Milling Line

A complete processing line from cleaning to packaging, delivering high-quality finished flour.

- Cleaning System: Multi-stage purification including a magnetic separator (TCXT20, 99% efficiency), High-efficiency vibrating screen (TQLZ80), and Destoner (TQSF80) to remove impurities, stones, and metals.

- Peeling & Degerming: Advanced emery and iron roller peelers (MNMF25A, LN200) ensure clean separation of bran and germ for premium flour quality.

- Milling Section: Features pneumatic Roller Mills (6F2250) and a Double-bin Plansifter (FSFJ 83x83x2) for precise granulation and separation.

- Packing System: Automated packing scale (DCS25) with a speed of 100-120 bags/h and 0.1% accuracy, suitable for 2-25kg bags.

4. Electrical Control & Automation

- Central Control: GGD Electrical control cabinets with PLC support and mobile remote monitoring capabilities.

- Safety: Integrated overload, leakage, and phase-loss protection with IP54 rated cabinets.

- For more information: