Maize Corn starch production line - Shanghai Genyond Technology Co., Ltd.

- Description details

-

Maize Corn starch production line

Average rate for each product

1)Starch: 63.5-66.5%

2)Embryo: 5.5-6.5%

3) Corn steep liquid:5-6 %

4) Fiber: 11-14%

5) Protein Powder: 4.5-6%

6)Recycle rate of Dried product:87.5-97.0 %1.Corn starch is mainly as the raw material to produce the starch derivatives and some fermentation products, such as glucose, maltose, fructose, dextrose monohydrate, sorbitol, lysine,

MSG, and other amino acids, which are widely used in food, beverage, pharmaceutical, animal feed, etc.

2.Corn starch is commonly used as a coagulant for pudding and other foods.

3.Paper making: Corn starch and its derivatives are very important chemical additives in the paper industry. The price is cheaper and more affordable than cassava starch,

so the proportion of corn starch used in the paper industry is increasing.

4.Food thicken: In our daily cooking food, the corn starch is often used to “thicken”, make soup more thick. Generally, use corn starch and water to stir evenly. Very convenient.

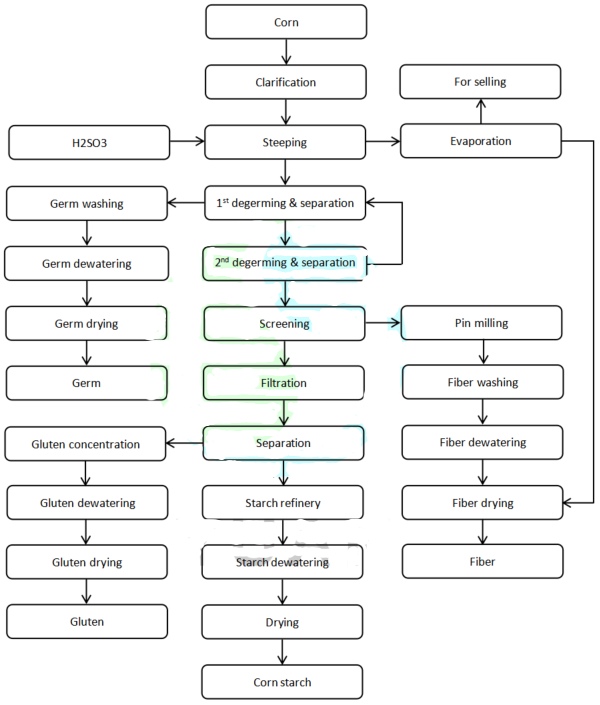

(1) Purifying: Before going to storage bin, pre-purifying is done to eliminate big and small foreign substance, which will be sent to germ cake collection section. The rotary screen placed beside the storage bin, has de-stoning and de-dusting functions. Purified corn is then sent to steeping section.

(2) Steeping: Counter current steeping principle is adopted to make corn become soft in steeping tank. Acid is heated and remains about 50°C when circulating in all tanks. Dipped corn is pumped to crashing stage.

(3) Sulfurous acid making: Sulfur is burned in furnace, getting SO2 gas, goes to absorbtion tower with china rings. Water is sprayed down, mixed with rising SO2 gas to get sulfurous acid.

(4) Crash and germ separation: Steeped corn is sent to 1st germ mill from wet corn storage bin. Crashed corn is pumped into 1st germ cyclone and screen to separate, and then goes to 2nd mill for further crush. Germ goes to 2nd germ cyclone, and then the light will be back to previous tank.

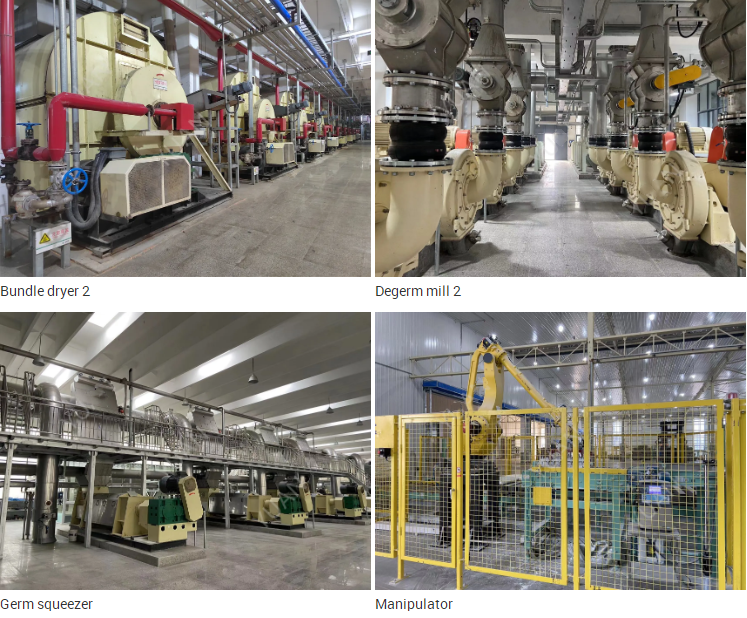

(5) Finely milling and fiber wash, dewater, drying: In pin mill, the degermed corn is multi--strongly crashed to remove fiber off. Fiber is sent to multi-stage washing screen for recovering the balance starch. Cleaned fiber goes to squeezer for dewatering then goes into bundle dryer for drying to mix with corn slurry for making animal feed product.

(6) Protein separation and starch washing: Starch milk goes to primary separator for gluten separation. Cleaned starch goes to 12 stages hydro cyclones for final washing to remove the tiny foreign items.

(7) Starch dewater and drying: Fine starch milk is dewatered by peeler centrifuge, the starch is sent to air flow dryer for making dry starch product in which moisture should be less than 14%. The finishing product is wrapped up through the packer and shipped out.

(8) Germ washing, dewater, drying, extraction oil and oil refinery: Germs from cyclone go to gravity arc screen for washing, then to squeezer for dewatering. Washed germs are sent to bundle dryer. Dried germ is fried and extracted then oil is filtered. Coarse oil is gotten at the end.

(9) Gluten concentration, dewater, drying: Gluten is concentrated by air floating vessels then goes to vacuum filter for further dewatering. Dewatered gluten goes to bundle dryer for making gluten meal product.

(10) Processing water recovery and steeping liquid evaporation: Corn steeping liquid is sent to evaporator for concentration then goes to fiber bundle dryer mixed with fibre to get animal feed. Process water from concentrator, dewater machine which contains SO2 and some insoluble material, can be used again to the whole system such as steeping and washing.

- About us

-

GENYOND MACHINERY INDUSTRIAL GROUP

Has 6 factories in China.

We specialize in food machine, medicine machine and packing machine.

Our main products include the following items:

Item 1, essential oil distillation machine, herbal extracting & concentration machine,pharmaceutical equipment

Item 2,dairy processing line to make pasturized milk, UHT milk, youghurt, cream,butter, cheese,ghee and so on.

Item 3, fruits and vegetable deep processing line (chips, canned food, juice, wine, vinegar, paste, jam, powder, candied food, pickles, frozen food,Dehydrated vegetable and so on); vegetable pre-processing line (washing, sorting, cutting, pitting, peeling, blanching and so on.)

Item 4,nuts processing line (coffee powder, nuts milk, nuts butter, paste and so on)

Item 5,fish, meat and egg processing line (canned fish, canned meat, egg cleaning sorting packing, egg liquid and egg powder and so on)

Item 6,grain and oil processing line (grain flour, starch, food oil and so on)

Item 7, salt and sugar processing line.

Item 8, food packing line

We have been in the design and production of food machine and medicine machine for more than 20 years. Our machines have been exported to more than 200 countries.

Our advantage is to offer you turnkey project. Our rich experience can help you on food production. We not only offer you the machine but also the processing technology and service on food and medicine production.

You just need to give us an idea on food production and we will make different proposals to help you to get the best solution on design, price and installation.

You are always welcome to visit us, we offer the free service on airport pickup, hotels, travelling in China.